Density of Aluminum

Aluminum, a silvery-white and remarkably lightweight metal, stands as the third most abundant element in the Earth’s crust.

Its unique combination of properties, particularly its low density, has cemented its role as a cornerstone material in modern engineering and everyday life.

From the aerospace industry to household packaging, the density of aluminum is a critical characteristic that dictates its suitability and performance.

This comprehensive exploration delves deep into the multifaceted nature of aluminum’s density, examining its fundamental definition, influencing factors, measurement techniques, and profound impact across various applications.

1. Introduction

The story of aluminum is one of rapid ascent in material science.

Though its ores are plentiful, its isolation as a pure metal was a challenge until the late 19th century.

With efficient extraction, aluminum’s low density and other strengths quickly drove its widespread use.

1.1 Definition of Density of Aluminum

Density, in physics and chemistry, is a fundamental intensive property of a substance, defined as its mass per unit volume.

It essentially quantifies how much material occupies a given space. For aluminum, engineers typically express this in grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³).

The density of aluminum specifically refers to the mass of aluminum metal contained within a specific, defined volume.

For pure, solid aluminum at room temperature (around 20°C or 68°F), the generally accepted density value is approximately:

- 2.70 g/cm³

- 2700 kg/m³

- 0.0975 lb/in³ (pounds per cubic inch)

- 168.5 lb/ft³ (pounds per cubic foot)

It’s crucial to note that this value pertains to commercially pure aluminum (e.g., 1xxx series alloys which are >99% Al).

The density can, and does, vary slightly with changes in alloy composition, temperature, and manufacturing processes, aspects we will explore in detail.

1.2 Why is Density of Aluminum Important?

The importance of aluminum’s density cannot be overstated.

Its relatively low value is a primary driver for its selection in countless applications, offering a significant weight advantage over many other structural metals like steel or copper.

- Weight Reduction & Efficiency: This is paramount in transportation. Lighter vehicles (cars, trains, aircraft, spacecraft) consume less fuel, leading to lower operational costs and reduced environmental impact. The density of aluminum directly contributes to improved fuel efficiency and performance.

- Strength-to-Weight Ratio: While pure aluminum is relatively soft, it can be alloyed with other elements to significantly enhance its mechanical strength. Many aluminum alloys boast an excellent strength-to-weight ratio, meaning they provide substantial structural integrity for their mass. This makes them ideal for applications where both strength and low weight are critical.

- Material Handling and Installation: Lighter materials are easier and often cheaper to transport, handle, and install. This can lead to reduced labor costs and faster construction or assembly times in industries like building and construction.

- Portability: For consumer goods, from laptops and smartphones to beverage cans and cookware, the low density of aluminum contributes to portability and user convenience.

- Design Flexibility: Engineers can design larger or more complex structures without incurring excessive weight penalties, allowing for innovative designs that might not be feasible with denser materials.

- Inertia Considerations: In applications involving moving parts, lower mass (due to lower density) means lower inertia. This translates to quicker acceleration and deceleration, which is beneficial in machinery and robotics.

Understanding the density of aluminum is not just an academic exercise; it’s a practical necessity for engineers, designers, manufacturers, and scientists working with this versatile metal.

It influences material selection, component design, cost analysis, and performance predictions.

2. Material Properties of Aluminum

Beyond its characteristic low density, aluminum possesses a suite of other material properties that contribute to its wide-ranging utility.

These properties are interconnected and often influence or are influenced by the density.

2.1 Chemical Composition

Commercially available aluminum is rarely 100% pure.

It typically contains trace amounts of other elements, either as impurities from the refining process or as deliberate additions to form alloys with specific characteristics.

- Pure Aluminum (1xxx series): These alloys are characterized by a minimum aluminum content of 99.0%. Common impurities include iron (Fe) and silicon (Si). The purity level affects properties like electrical conductivity and corrosion resistance.

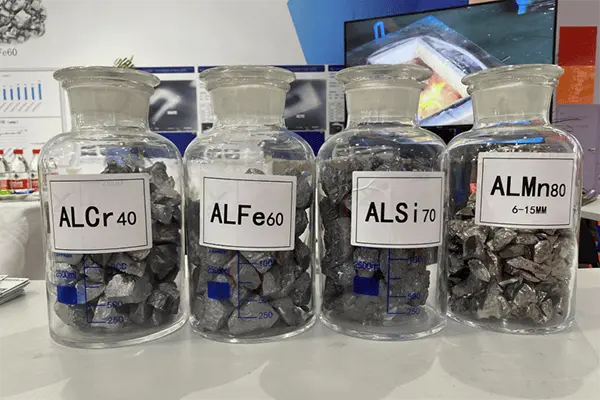

- Alloying Elements: To enhance mechanical properties, formability, corrosion resistance, or other characteristics, aluminum is intentionally mixed with elements such as copper (Cu), magnesium (Mg), silicon (Si), manganese (Mn), zinc (Zn), and lithium (Li). Each of these elements has its own atomic weight and density, and their addition will inevitably alter the overall density of the aluminum alloy. For instance, adding heavier elements like copper or zinc will tend to increase the alloy’s density, while lighter elements like lithium will decrease it.

The precise chemical composition is fundamental, as it dictates not only the density but also the entire spectrum of physical and mechanical behaviors of the material.

2.2 Physical Properties

- Density: Approximately 2.70 g/cm³—about one-third the density of steel (≈ 7.85 g/cm³) or copper (≈ 8.96 g/cm³), which gives aluminum its lightweight character.

- Melting Point: About 660.3 °C (1220.5 °F), lower than that of iron or steel, which reduces energy consumption during casting and processing (alloying can slightly shift this range).

- Thermal Conductivity: Roughly 237 W/(m·K) at room temperature, making aluminum an excellent heat conductor used in heat sinks, cookware, and heat exchangers.

- Electrical Conductivity: Around 61% of the International Annealed Copper Standard (≈ 37.7 × 10⁶ S/m). Although copper is more conductive by volume, aluminum’s lower density means an aluminum conductor of equal resistance weighs about half as much—ideal for overhead power lines.

- Reflectivity: Polished aluminum reflects over 90% of visible light and over 95% of infrared radiation, making it valuable in mirrors, reflective insulation, and decorative finishes.

- Magnetic Behavior: Paramagnetic and essentially unaffected by static magnetic fields, which is beneficial in electrical and electronic applications sensitive to magnetic interference.

- Coefficient of Thermal Expansion: Approximately 23 × 10⁻⁶ /°C at 20 °C, indicating that aluminum expands and contracts more with temperature changes than materials like steel—important to accommodate in multi-material designs.

2.3 Mechanical Properties

Mechanical properties describe how a material responds to applied forces or loads. These properties are crucial for structural and load-bearing applications. For aluminum, they can vary dramatically depending on its purity and alloying.

Tensile Strength:

This measures the maximum stress a material can withstand while being stretched or pulled before necking.

Pure aluminum is relatively weak, with a tensile strength around 90 MPa (13,000 psi).

However, alloying and heat treatments can increase this to over 700 MPa (100,000 psi) for some high-strength alloys (e.g., 7xxx series).

Yield Strength:

This is the stress at which a material begins to deform plastically (permanently).

It’s a critical design parameter. For pure aluminum, it’s around 35 MPa (5,000 psi), but can exceed 600 MPa (87,000 psi) in strong alloys.

Ductility/Formability:

Aluminum is generally a very ductile material, meaning it can be drawn into wires or deformed significantly without fracturing.

This makes it highly formable by processes like rolling, extrusion, drawing, and stamping.

Alloying can reduce ductility.

Hardness:

This is the material’s resistance to localized plastic deformation, such as scratching or indentation.

Pure aluminum is soft (around 20-30 Brinell Hardness), but alloying and work hardening can increase this significantly.

Fatigue Strength:

This is the ability of a material to withstand cyclic loading.

Aluminum alloys have varying fatigue characteristics, which are critical in aerospace and automotive applications.

Fracture Toughness:

This measures a material’s resistance to crack propagation.

Modulus of Elasticity (Young’s Modulus):

This is a measure of stiffness, or resistance to elastic deformation.

For aluminum, it’s approximately 69 GPa (10,000 ksi), which is about one-third that of steel.

This lower stiffness means aluminum components will deflect more than steel components of the same geometry under the same load.

To achieve similar stiffness, aluminum sections often need to be designed with larger cross-sectional areas or more complex geometries, but even then, they are often still lighter due to the significant density advantage.

The interplay of these physical and mechanical properties, combined with its low density of aluminum, defines its versatility and performance envelope.

3. Factors Affecting Density of Aluminum

While we often cite a single value for the density of pure aluminum, several factors can cause this value to deviate in practical scenarios, especially when dealing with aluminum alloys.

3.1 Alloy Composition

This is the most significant factor influencing the density of aluminum products.

As mentioned, pure aluminum (typically 1xxx series alloys) has a density of about 2.70 g/cm³.

When other elements are intentionally added to create alloys, the resulting density becomes a weighted average of the densities of the constituent elements.

- Heavier Alloying Elements: Elements like copper (density ~8.96 g/cm³), zinc (density ~7.14 g/cm³), and iron (density ~7.87 g/cm³) are denser than aluminum. Adding them will generally increase the overall density of the alloy. For example, 2xxx series (Al-Cu) and 7xxx series (Al-Zn-Mg-Cu) alloys tend to be slightly denser than pure aluminum.

- Lighter Alloying Elements: Elements like magnesium (density ~1.74 g/cm³) and lithium (density ~0.534 g/cm³) are less dense than aluminum. Their addition will decrease the alloy’s density. This is particularly notable in aluminum-lithium (Al-Li) alloys (e.g., 2xxx and 8xxx series), which are specifically designed for aerospace applications where every gram saved is critical. Silicon (density ~2.33 g/cm³) is also lighter than aluminum.

- Elements with Similar Density: Manganese (density ~7.21 g/cm³, though often added in small amounts) is denser, but its effect might be moderated by other elements.

The precise percentage of each alloying element will determine the final density.

For example, an alloy with 5% copper will be denser than an alloy with 1% copper, all other things being equal.

This variability is why density specifications for aluminum alloys often provide a range or a nominal value specific to that grade.

3.2 Manufacturing Process

The way an aluminum product is manufactured can also introduce variations in its effective density, primarily through the creation or elimination of internal voids or changes in microstructure.

Porosity in Castings

During casting (sand, die, investment), molten aluminum solidifies in a mold.

Gas bubbles (often hydrogen) or shrinkage can form microscopic or larger pores, reducing the part’s bulk density compared to a fully dense wrought alloy. Minimizing these voids is essential for quality.

Sintering in Powder Metallurgy

Aluminum powder is pressed into a shape and heated below its melting point to bond the particles.

If sintering is incomplete, residual porosity remains, lowering the final part’s density and strength.

Work Hardening (Cold Working)

Cold processes like rolling, drawing, or forging introduce dislocations and refine grains.

While they mainly increase strength and hardness, they can also close tiny voids and slightly increase density (usually by less than 1%), though this effect is minor.

Heat Treatment

Solution treatment and quenching create a supersaturated solid solution, and subsequent aging precipitates fine intermetallic particles.

These phase changes primarily affect mechanical properties but can also cause very slight overall density shifts due to differences in lattice parameters and phase densities.

3.3 Temperature

Like most materials, aluminum expands when heated and contracts when cooled. This change in volume directly affects its density (since mass remains constant).

Thermal Expansion:

The coefficient of thermal expansion (α or λ) quantifies how much a material’s dimensions change per degree Celsius (or Fahrenheit) change in temperature.

For aluminum, this is approximately 23.1 x 10⁻⁶ /°C.

Volume Expansion:

For isotropic materials, the volumetric coefficient of thermal expansion (β) is approximately 3α. So, for aluminum, β ≈ 3 * 23.1 x 10⁻⁶ /°C = 69.3 x 10⁻⁶ /°C.

Density Change:

If the initial density at temperature T₀ is ρ₀ and the initial volume is V₀, then ρ₀ = m/V₀.

When the temperature changes by ΔT, the new volume V will be V = V₀ (1 + βΔT).

The new density ρ will be ρ = m/V = m / [V₀ (1 + βΔT)] = ρ₀ / (1 + βΔT).For an increase in temperature (ΔT > 0), the volume increases, and thus the density decreases.

For a decrease in temperature (ΔT < 0), the volume decreases, and thus the density increases.

Example:

If ρ₀ = 2.70 g/cm³ at 20°C, and we heat it to 100°C (ΔT = 80°C):

βΔT = (69.3 x 10⁻⁶ /°C) * 80°C = 0.005544

New density ρ = 2.70 g/cm³ / (1 + 0.005544) ≈ 2.70 / 1.005544 ≈ 2.685 g/cm³

This shows a noticeable, albeit small, decrease in density with a moderate temperature increase.

For high-precision calculations or applications involving significant temperature swings (e.g., aerospace components, engines), this thermal effect on the density of aluminum must be considered.

4. Density of Aluminum Alloys

The versatility of aluminum is massively expanded through alloying.

By combining aluminum with other elements, metallurgists can tailor its properties, including its density, to meet specific application demands.

4.1 Introduction to Aluminum Alloys

An aluminum alloy is a metallic substance in which aluminum is the predominant metal, intentionally mixed with one or more other elements (metals or non-metals) to enhance or impart specific characteristics.

Common Alloying Elements and Their General Effects:

- Silicon (Si): Improves fluidity and reduces shrinkage in castings, enhances strength. Lowers density slightly. (Density of Si ~2.33 g/cm³)

- Copper (Cu): Significantly increases strength and hardness, especially after heat treatment. Improves machinability. Increases density. (Density of Cu ~8.96 g/cm³)

- Magnesium (Mg): Provides good strength through solid-solution strengthening and work hardening, excellent corrosion resistance (especially in marine environments). Lowers density. (Density of Mg ~1.74 g/cm³)

- Manganese (Mn): Increases strength moderately, improves strain hardening characteristics. Increases density slightly. (Density of Mn ~7.21 g/cm³, but typically added in small amounts up to ~1.5%)

- Zinc (Zn): When combined with magnesium (and sometimes copper), produces the highest strength heat-treatable aluminum alloys. Increases density. (Density of Zn ~7.14 g/cm³)

- Lithium (Li): Significantly increases stiffness (modulus of elasticity) and strength while notably decreasing density. Primary element in Al-Li alloys for aerospace. (Density of Li ~0.534 g/cm³)

- Iron (Fe): Often an impurity, but sometimes added to improve strength at elevated temperatures in casting alloys. Increases density.

- Chromium (Cr): Improves stress corrosion resistance and controls grain structure.

- Titanium (Ti) & Boron (B): Used as grain refiners.

Classification of Aluminum Alloys:

Aluminum alloys are broadly classified into two main categories based on their primary manufacturing method:

- Wrought Alloys: These are shaped by mechanical working processes like rolling, extrusion, forging, or drawing. They are designated by a four-digit system established by The Aluminum Association.

1xxx series:Min. 99.00% aluminum (essentially pure aluminum). Lowest strength, excellent corrosion resistance, high electrical/thermal conductivity. Density ~2.70 g/cm³.2xxx series:Alloyed primarily with Copper (Cu). Heat-treatable, high strength, good fatigue resistance. Used in aerospace. Density typically 2.75 – 2.85 g/cm³.3xxx series:Alloyed primarily with Manganese (Mn). Non-heat-treatable, moderate strength, good formability. Used for beverage cans, cookware. Density ~2.73 g/cm³.4xxx series:Alloyed primarily with Silicon (Si). Non-heat-treatable (some are), lower melting point. Used as welding wire and brazing alloy; some casting alloys are in this category. Density varies, often slightly lower than pure Al if Si is the main addition.5xxx series:Alloyed primarily with Magnesium (Mg). Non-heat-treatable, moderate to high strength (from work hardening), excellent corrosion resistance in marine environments. Used in shipbuilding, truck bodies. Density typically 2.55 – 2.70 g/cm³.6xxx series:Alloyed with Magnesium (Mg) and Silicon (Si) (forming Mg₂Si). Heat-treatable, good strength, good formability, good corrosion resistance, weldable. Very common for extrusions (architectural, automotive). Density ~2.70 g/cm³.7xxx series:Alloyed primarily with Zinc (Zn), often with Mg and Cu. Heat-treatable, highest strength aluminum alloys. Used in aerospace, high-performance sporting goods. Density typically 2.80 – 2.90 g/cm³.8xxx series:Alloyed with other elements, notably Lithium (Li) in some cases. Specialized alloys (e.g., Al-Li for aerospace). Density can be significantly lower (e.g., ~2.55 g/cm³ for some Al-Li).

- Cast Alloys: These are shaped by pouring molten metal into molds. They are designated by a system that often involves three digits, a decimal point, and another digit (e.g., xxx.x).

- Common alloying elements include silicon, copper, and magnesium.

- Densities vary widely based on composition, similar to wrought alloys. For example, Al-Si casting alloys (like A356, A380) are very common. A356 (Al-7Si-0.3Mg) has a density around 2.68 g/cm³. A380 (Al-8.5Si-3.5Cu) is denser, around 2.74 g/cm³.

4.2 Density Variation of Different Alloys

The density of an aluminum alloy is fundamentally a function of the densities and proportions of its constituent elements.

It can be approximated by the “rule of mixtures” for ideal solutions, though intermetallic compound formation and atomic packing efficiencies can cause slight deviations.

This clearly illustrates why:

- Adding lithium (ρ = 0.534 g/cm³) dramatically reduces alloy density.

- Adding copper (ρ = 8.96 g/cm³) or zinc (ρ = 7.14 g/cm³) increases it.

- Adding magnesium (ρ = 1.74 g/cm³) or silicon (ρ = 2.33 g/cm³) slightly reduces it.

The specific combination and percentages of these elements fine-tune the final density of the aluminum alloy.

4.3 Examples of Common Aluminum Alloys and Their Densities

The following table provides nominal density values for some widely used aluminum alloys at room temperature.

These are typical values and can vary slightly based on the exact composition within the specified range for that alloy, temper, and manufacturing source.

| Alloy Designation | Primary Alloying Elements | Typical Density (g/cm³) | Typical Density (kg/m³) | Typical Density (lb/in³) | Notes |

|---|---|---|---|---|---|

| Wrought Alloys | |||||

| 1100 | 99.0% min Al | 2.71 | 2710 | 0.0979 | Commercially pure, excellent formability |

| 2014 | Cu, Mg, Si, Mn | 2.80 | 2800 | 0.101 | High strength, aerospace |

| 2024 | Cu, Mg, Mn | 2.78 | 2780 | 0.100 | High strength, fatigue resistance, aerospace |

| 3003 | Mn, Cu | 2.73 | 2730 | 0.0986 | General purpose, good formability |

| 5005 | Mg | 2.70 | 2700 | 0.0975 | Architectural, anodizing quality |

| 5052 | Mg, Cr | 2.68 | 2680 | 0.0968 | Marine applications, good corrosion res. |

| 5083 | Mg, Mn, Cr | 2.66 | 2660 | 0.0961 | Higher strength 5xxx, marine, cryogenic |

| 6061 | Mg, Si, Cu, Cr | 2.70 | 2700 | 0.0975 | Very versatile, structural, extrusions |

| 6063 | Mg, Si | 2.69 | 2690 | 0.0972 | Architectural extrusions, good finish |

| 7075 | Zn, Mg, Cu, Cr | 2.81 | 2810 | 0.101 | Very high strength, aerospace, frames |

| 8090 (Al-Li) | Li, Cu, Mg | ~2.55 | ~2550 | ~0.0921 | Aerospace, low density, high stiffness |

| Cast Alloys | |||||

| A356.0 | Si, Mg | 2.68 | 2680 | 0.0968 | Excellent castability, good strength |

| A380.0 | Si, Cu | 2.74 | 2740 | 0.0989 | Common die casting alloy |

| A201.0 | Cu, Ag, Mg | 2.79 | 2790 | 0.1008 | High strength casting alloy |

The table highlights how different alloys influence aluminum’s density, showing that specific composition determines the exact value.

5. Measuring the Density of Aluminum

Accurately determining the density of aluminum samples is crucial for quality control, material identification, and research.

Several methods can be employed, each with its own principles, advantages, and limitations.

5.1 Density Measurement Methods

-

Archimedes’ Principle (Buoyancy Method / Hydrostatic Weighing):

This is one of the most common and straightforward methods for solid, non-porous samples.

- Principle: Archimedes’ principle states that an object submerged in a fluid experiences an upward buoyant force equal to the weight of the fluid displaced by the object.

- Advantages: Relatively simple, widely applicable for solid objects.

- Limitations: Not suitable for samples that absorb the fluid or have open porosity (unless sealed). Accuracy depends on the precision of the balance, temperature control (for fluid density), and minimizing air bubbles.

-

Geometric Measurement (Direct Mass/Volume):

For regularly shaped objects (e.g., cubes, cylinders, rectangular blocks), density can be determined by measuring its dimensions to calculate volume, and then measuring its mass.

- Procedure:

- Measure the relevant dimensions (length, width, height, diameter) using precision instruments like calipers or micrometers.

- Calculate the volume (V) using the appropriate geometric formula.

- Measure the mass (m) of the object using an accurate balance.

- Density (ρ) = m / V.

- Advantages: Conceptually very simple.

- Limitations: Only practical for regular shapes. Accuracy highly dependent on the precision of dimensional measurements and the regularity of the shape. Internal voids not accounted for if not apparent.

- Procedure:

-

Pycnometry (Gas or Liquid Pycnometer):

Pycnometers are used to determine the volume of a sample, often for powders or irregularly shaped solids, by measuring fluid displacement.

- Gas Pycnometer (e.g., Helium Pycnometer):

- Principle: Uses Boyle’s Law (P₁V₁ = P₂V₂). A known volume of gas (usually helium, as it’s inert and small enough to penetrate fine pores) is allowed to expand into a chamber containing the sample. By measuring pressure changes, the volume occupied by the solid sample can be determined very accurately.

- Procedure: The sample is placed in a sealed chamber of known volume. Gas at a known pressure is introduced. The gas then expands into another reference chamber, and the new equilibrium pressure is measured. The volume of the sample is calculated based on these pressures and known chamber volumes.

- Advantages: Highly accurate, non-destructive, can measure true density (excluding open pores). Good for powders and porous materials.

- Limitations: More complex and expensive equipment.

- Liquid Pycnometer: A specific type of flask with a precisely known volume. The sample is added, and the pycnometer is filled with a liquid of known density. The volume of the sample is found by the difference in the volume of liquid required to fill the pycnometer with and without the sample.

- Gas Pycnometer (e.g., Helium Pycnometer):

-

Sink-Float Method:

This is a comparative method, more for sorting or rough estimation than precise measurement.

- Procedure: Samples are placed in a series of liquids with known, graduated densities. A sample will sink if it is denser than the liquid, float if it is less dense, and remain suspended if its density matches the liquid’s density.

- Advantages: Quick for relative comparisons.

- Limitations: Provides a density range rather than an exact value. Requires a set of calibrated density liquids.

5.2 Precision and Accuracy

When measuring the density of aluminum, understanding the concepts of precision and accuracy is vital.

- Accuracy: How close a measured value is to the true or accepted value. Factors affecting accuracy include calibration of instruments (balance, calipers, pycnometer), correctness of the known density of the immersion fluid, and adherence to standard procedures.

- Precision: How close repeated measurements of the same quantity are to each other (reproducibility). Factors affecting precision include the resolution of the instruments, operator skill, stability of environmental conditions (temperature), and consistency in sample preparation.

For high-quality density measurements:

- Use calibrated and high-resolution instruments.

- Control temperature, especially for the immersion fluid in Archimedes’ method.

- Ensure samples are clean and dry (for air weighing).

- Minimize air bubbles clinging to submerged samples.

- Take multiple readings and average them.

- Account for the density of air in highly precise weighings (air buoyancy correction).

Standardized test methods, such as those from ASTM International (e.g., ASTM B962 for density of powder metallurgy materials, ASTM D792 for density by displacement), provide detailed procedures to ensure reliable results.

6. Density of Aluminum Applications

The numerical value of aluminum’s density finds direct and indirect application in various scientific and industrial domains, beyond just material selection.

6.1 Engineering Design and Analysis

- Weight Calculation: One of the most fundamental uses. Engineers use the density to calculate the mass of components and structures based on their volume (derived from CAD models or drawings). This is essential for:

- Structural load calculations (dead loads).

- Determining shipping weights and costs.

- Ensuring products meet weight specifications (e.g., in aerospace, automotive, portable electronics).

- Stress Analysis & Finite Element Analysis (FEA): In FEA simulations, density is a required material property to accurately model gravitational forces and dynamic behavior (e.g., vibrations, impact response where mass distribution is critical).

- Center of Gravity Calculations: For complex assemblies, knowing the density of individual aluminum components helps in determining the overall center of gravity, which is crucial for stability and performance in vehicles, aircraft, and machinery.

- Buoyancy and Flotation Calculations: In marine design, aluminum’s density relative to the fluid it displaces plays a crucial role in ensuring flotation or submersion.

6.2 Material Identification and Verification

Alloy Verification:

Since different aluminum alloys have distinct (though sometimes overlapping) density ranges, measuring the density of a sample can be a quick, non-destructive preliminary method to verify if it matches the specified alloy.

A significant deviation from the expected density might indicate the wrong alloy, incorrect composition, or excessive porosity.

Distinguishing from Other Metals:

Aluminum’s density is markedly different from many other common metals like steel, copper, or titanium.

A simple density check can often help in sorting mixed materials or identifying an unknown metal sample.

Purity Assessment (Less Common):

For highly pure aluminum, deviations in density could theoretically indicate contamination, though other analytical techniques are usually more sensitive for this purpose.

6.3 Quality Control in Manufacturing

Porosity Detection in Castings/PM Parts:

As discussed, porosity reduces the bulk density of a part. Measuring the density of manufactured components and comparing it to the theoretical (fully dense) density of the alloy provides a quantitative measure of porosity.

This is a common quality control check for castings and powder metallurgy parts to ensure they meet mechanical strength requirements.

Percent Porosity ≈ [(Theoretical Density – Measured Density) / Theoretical Density] x 100%

Consistency of Raw Materials:

Manufacturers may check the density of incoming raw aluminum stock (billets, ingots, sheets) to ensure it conforms to specifications before processing.

Process Monitoring:

Changes in the density of finished products over time can indicate drifts or problems in the manufacturing process (e.g., issues with molten metal treatment in casting, sintering parameters in PM).

The density of aluminum, therefore, serves as a valuable metric throughout the lifecycle of an aluminum product, from initial design and material selection to manufacturing quality assurance and even post-service analysis.

7. Comparison of Aluminum Density with Other Materials

To fully appreciate the significance of aluminum’s low density, it’s instructive to compare it with other common engineering materials, both metallic and non-metallic.

7.1 Comparison with Density of Other Metals

Aluminum stands out among structural metals for its lightness.

Table 2: Density Comparison of Aluminum with Other Common Metals

| Metal | Typical Density (g/cm³) | Typical Density (kg/m³) | Ratio to Aluminum Density (Approx.) |

|---|---|---|---|

| Aluminum (Al) | 2.70 | 2700 | 1.0 |

| Magnesium (Mg) | 1.74 | 1740 | 0.64 |

| Titanium (Ti) | 4.51 | 4510 | 1.67 |

| Zinc (Zn) | 7.14 | 7140 | 2.64 |

| Tin (Sn) | 7.31 | 7310 | 2.71 |

| Iron (Fe) / Steel | 7.85 – 7.87 | 7850 – 7870 | 2.91 |

| Brass (Cu-Zn) | 8.40 – 8.70 | 8400 – 8700 | 3.1 – 3.2 |

| Copper (Cu) | 8.96 | 8960 | 3.32 |

| Nickel (Ni) | 8.90 | 8900 | 3.30 |

| Silver (Ag) | 10.49 | 10490 | 3.89 |

| Lead (Pb) | 11.34 | 11340 | 4.20 |

| Gold (Au) | 19.32 | 19320 | 7.16 |

| Platinum (Pt) | 21.45 | 21450 | 7.94 |

Key Observations:

- Magnesium: The only common structural metal significantly lighter than aluminum. However, magnesium can have challenges with corrosion and formability compared to some aluminum alloys.

- Titanium: About 67% denser than aluminum, but offers exceptional strength-to-weight ratios (especially at high temperatures) and corrosion resistance, making it a competitor in high-performance applications like aerospace, albeit at a higher cost.

- Steel: Nearly three times denser than aluminum. This is the most common comparison. While steel is generally stronger and stiffer per unit volume, aluminum alloys can offer superior strength-to-weight and stiffness-to-weight ratios, making aluminum the choice when weight reduction is paramount.

- Copper and Brass: Over three times denser than aluminum. Chosen for their electrical conductivity (copper) or specific mechanical/aesthetic properties (brass), not for low weight.

This comparison starkly highlights why the low density of aluminum is such a valuable asset.

7.2 Comparison with Density of Non-Metals

Aluminum also competes with various non-metallic materials, especially plastics and composites, in applications where low weight is crucial.

| Material | Typical Density (g/cm³) | Typical Density (kg/m³) | Ratio to Aluminum Density (Approx.) |

|---|---|---|---|

| Aluminum (Al) | 2.70 | 2700 | 1.0 |

| Water | 1.00 | 1000 | 0.37 |

| Polyethylene (PE) | 0.91 – 0.97 | 910 – 970 | 0.34 – 0.36 |

| Polypropylene (PP) | 0.90 – 0.91 | 900 – 910 | 0.33 |

| Polystyrene (PS) | 1.04 – 1.09 | 1040 – 1090 | 0.39 – 0.40 |

| PVC (Polyvinyl Chloride) | 1.30 – 1.45 | 1300 – 1450 | 0.48 – 0.54 |

| PET (Polyethylene Tereph.) | 1.38 – 1.40 | 1380 – 1400 | 0.51 – 0.52 |

| Nylon (Polyamide) | 1.13 – 1.15 | 1130 – 1150 | 0.42 |

| ABS (Acrylonitrile But…) | 1.03 – 1.08 | 1030 – 1080 | 0.38 – 0.40 |

| Wood (Oak) | 0.60 – 0.90 | 600 – 900 | 0.22 – 0.33 |

| Wood (Pine) | 0.35 – 0.50 | 350 – 500 | 0.13 – 0.19 |

| Glass (Soda-lime) | 2.44 – 2.58 | 2440 – 2580 | 0.90 – 0.96 |

| Carbon Fiber Reinforced Polymer (CFRP) | 1.50 – 1.80 | 1500 – 1800 | 0.56 – 0.67 |

| Glass Fiber Reinforced Polymer (GFRP) | 1.80 – 2.10 | 1800 – 2100 | 0.67 – 0.78 |

| Concrete | 2.30 – 2.50 | 2300 – 2500 | 0.85 – 0.93 |

This broader comparison shows that while aluminum is not the absolute lightest material available, it occupies a “sweet spot” offering an excellent balance of low density, good mechanical properties (especially when alloyed), good thermal/electrical conductivity, corrosion resistance, formability, and recyclability, often at a competitive cost point.

The choice between aluminum and these other materials depends heavily on the specific requirements of the application.

8. Applications of Aluminum Alloy Density

The practical impact of the density of aluminum alloys is most evident in industries where weight is a critical performance or cost factor.

Engineers choose different alloys not just for their absolute density, but for how that density complements key properties like strength, stiffness, corrosion resistance, and manufacturability.

8.1 Aerospace Applications

The aerospace industry was one of the earliest and remains one of the largest consumers of high-performance aluminum alloys.

Every kilogram of weight saved on an aircraft translates to improved fuel efficiency, increased payload capacity, or enhanced performance (range, maneuverability).

- Airframe Structures: Alloys like 2024 (Al-Cu-Mg) and 7075 (Al-Zn-Mg-Cu), despite being slightly denser than pure aluminum (around 2.78 g/cm³ and 2.81 g/cm³ respectively), offer exceptionally high strength-to-weight ratios. They are extensively used for fuselage skins, wing structures, spars, and other load-bearing components.

- Aluminum-Lithium (Al-Li) Alloys: Series like 2xxx (e.g., 2195) and 8xxx (e.g., 8090) are specifically engineered for aerospace. Lithium, being the lightest metallic element, reduces the alloy’s density by up to 10-15% (e.g., down to ~2.55 g/cm³) while simultaneously increasing its stiffness (elastic modulus). This dual benefit makes them highly attractive for reducing structural weight in aircraft and spacecraft, leading to significant fuel savings over the vehicle’s operational life.

- Forgings and Extrusions: Complex aerospace components are often forged or extruded from aluminum alloys. The consistent density of aluminum ensures predictable weight and performance characteristics for these critical parts.

8.2 Automotive Applications

The automotive industry increasingly utilizes aluminum alloys to reduce vehicle weight, thereby improving fuel economy, reducing emissions, and enhancing performance (acceleration, handling).

- Body Panels and Structures (Body-in-White): Alloys from the 5xxx (Al-Mg) and 6xxx (Al-Mg-Si) series are used for hoods, doors, trunk lids, and structural components. For instance, 6061-T6 (density ~2.70 g/cm³) is very common. Using aluminum instead of steel for these parts can lead to substantial weight savings.

- Engine Components: Cast aluminum alloys (e.g., A356, A380 with densities around 2.68-2.74 g/cm³) are standard for engine blocks, cylinder heads, pistons, and intake manifolds. Besides weight reduction, aluminum’s good thermal conductivity helps with heat dissipation.

- Wheels: Forged or cast aluminum alloy wheels are popular for their aesthetic appeal and weight reduction compared to steel wheels, which can improve handling by reducing unsprung mass.

- Chassis and Suspension Components: High-strength aluminum alloys are used for control arms, knuckles, and subframes to reduce weight and improve vehicle dynamics.

- Electric Vehicles (EVs): Weight reduction is even more critical for EVs to maximize battery range. Aluminum supports battery enclosures and vehicle structures, offering protection, thermal management, and lightweight strength.

8.3 Packaging Industry

Aluminum’s low density, combined with its formability, impermeability, and corrosion resistance, makes it an ideal material for various packaging applications.

- Beverage Cans: Dominated by 3xxx series alloys (like 3003 or 3104 for the can body, density ~2.73 g/cm³) and 5xxx series alloys (like 5182 for the lid). The low density of aluminum significantly reduces the weight of packaged beverages, leading to lower transportation costs and easier handling for consumers.

- Food Containers and Trays: Aluminum foil (often from 1xxx series alloys) and shallow containers are used for food packaging due to their light weight, barrier properties, and ability to withstand cooking temperatures.

- Flexible Packaging (Laminates): Packaging manufacturers often laminate thin aluminum foil with plastics and paper to create lightweight, high-barrier flexible packaging for coffee, snacks, and pharmaceutical products.

- Aerosol Cans and Tubes: Used for personal care products and pharmaceuticals, leveraging aluminum’s light weight and formability.

In all these packaging examples, the low density of aluminum directly contributes to material efficiency (less material used per package by weight), reduced shipping costs, and consumer convenience. Its excellent recyclability further enhances its sustainability profile in this sector.

Other sectors where aluminum alloy density plays a crucial role include:

- Marine: 5xxx series alloys for boat hulls and superstructures due to their good strength-to-weight ratio and corrosion resistance in saltwater.

- Rail Transportation: For passenger cars and freight wagons to reduce weight and improve energy efficiency.

- Consumer Electronics: For casings of laptops, tablets, smartphones, and TVs, offering a premium feel with low weight.

- Sporting Goods: Bicycle frames (6061, 7005), baseball bats, ski poles.

- Construction: Window frames, curtain walls, roofing, and facade systems where ease of handling and reduced structural load are beneficial.

9. Conclusion

The density of aluminum, nominally around 2.70 g/cm³, is one of its most defining and valuable characteristics.

This inherent lightness, approximately one-third that of steel, positions aluminum as a material of choice in a vast spectrum of applications where weight reduction, efficiency, and performance are paramount.

Comparing aluminum with other metals and non-metals underscores its unique position.

It offers a compelling balance of low density with good strength (especially when alloyed), excellent thermal and electrical conductivity, high reflectivity, corrosion resistance, formability, and recyclability.

This favorable combination makes it indispensable in aerospace, automotive, packaging, construction, and consumer electronics, among other fields.

In essence, the density of aluminum is not merely a static number but a dynamic property that interacts with composition and processing to deliver a family of materials that are fundamental to technological advancement and everyday convenience.

Understanding its nuances allows engineers and designers to harness aluminum’s full potential, driving innovation and efficiency across global industries.

The lightweight revolution, in many ways, draws strength from the well-understood and remarkable density of this versatile metal.

Leave a Reply