5052 Aluminium blad

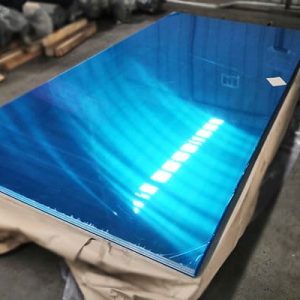

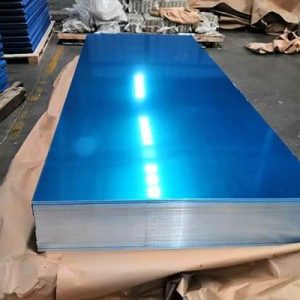

5052 aluminium blad behoort tot de 5000 serie aluminium legering. Het belangrijkste toegevoegde element is mg. Het wordt verkregen door de aluminiumlegering te rollen. Het heeft een sterke corrosieweerstand en uitstekende bewerkbaarheid en wordt veel gebruikt.

1. 5052 Aluminium bladoverzicht

5052 aluminum sheet represents one of the most widely used aluminum alloys in sheet form.

This material enjoys a strong reputation among engineers and fabricators alike due to its superb balance of strength, Vormbaarheid, en uitstekende corrosieweerstand.

1.1 Definitie van 5052 Aluminium blad

5052 aluminum sheet defines a non-heat-treatable alloy within the 5000 series that uses magnesium as the primary alloying element along with a trace addition of chromium.

Manufacturers produce 5052 aluminum sheet by starting with high-purity aluminum and blending in the alloying elements to achieve an optimal balance.

The alloy typically contains approximately 97.2%–98.9% aluminum, with magnesium levels ranging between 2.2% En 2.8% and chromium levels from 0.15% naar 0.35%.

These percentages produce a material with improved mechanical strength, Verbeterde vermoeidheidsweerstand, en een uitstekende weerstand tegen corrosieve omgevingen.

1.2 Overzicht van het belang ervan in verschillende industrieën

5052 Aluminium blad speelt een cruciale rol in veel industrieën.

Zijn uitstekende weerstand tegen corrosie, Vooral in mariene atmosferen, Samen met zijn uitzonderlijke vormbaarheid, Maak het onmisbaar in zowel traditionele als geavanceerde toepassingen.

Veel industrieën profiteren van 5052 aluminium blad op de volgende manieren:

- Mariene toepassingen: De legering is bestand tegen zoutwatercorrosie, waardoor het een topkeuze is voor scheepsbouw, mariene structuren, en offshore -apparatuur.

- Ruimtevaart en transport: Lichtgewicht ontwerp gecombineerd met een hoge vermoeidheidsweerstand en goede lasbaarheid ondersteunt het gebruik ervan in ruimtevaartcomponenten, vliegtuighuiden, en voertuigchassis.

- Auto -industrie: Ingenieurs zijn voorkeur 5052 voor carrosseriepanelen, beugels, en andere structurele componenten vanwege de sterkte-gewichtsverhouding.

- Bouw en constructie: In architectural applications, the material exhibits durability and aesthetic appeal when used in cladding, dakbedekking, en decoratieve panelen.

- Industrial and Electronic Sectors: Its excellent mechanical properties suit the production of pressure vessels, elektronische behuizingen, and heat exchangers.

- General Sheet Metal Fabrication: Its ease of cold working enables manufacturers to produce precision parts such as containers, leidingwerk, and customized fabricated assemblies.

The alloy’s versatility has led to robust global demand, where its performance characteristics deliver both economic and technical benefits.

Industries choose 5052 aluminum sheet when they require a material that meets strict durability, veiligheid, and sustainability standards.

2. Materiaaleigenschappen en prestatieparameters

A deep understanding of the material properties and performance parameters of 5052 aluminum sheet enables its optimal application.

This section explains the alloy classification, samenstelling, and the key mechanical, physical, and environmental properties that define this material.

2.1 Legering classificatie en compositie

5052 belongs to the 5xxx series aluminum alloys that primarily use magnesium as the key alloying element.

Its composition design helps achieve a well-balanced combination of strength, ductiliteit, en corrosieweerstand.

2.1.1 Hoofdcomponenten

The primary component of 5052 aluminum sheet is high-purity aluminum, which forms the matrix.

Typisch, the aluminum content accounts for approximately 97.2% naar 98.9% of the alloy.

This high aluminum base provides excellent conductivity, low density, and inherent malleability.

2.1.2 Hulpelementen

Magnesium plays a crucial role in enhancing the material’s strength through solid solution strengthening.

In 5052 aluminium blad, the magnesium content usually ranges between 2.2% En 2.8%.

The small addition of chromium—approximately 0.15% to 0.35%—further contributes to improved corrosion resistance and stabilization of the microstructure.

2.1.3 Spoor elementen en onzuiverheden

To maintain consistency and high performance, manufacturers strictly control the levels of impurities and trace elements.

The common controlled elements include:

- Ijzer (Fe): Kept below 0.40%

- Silicium (En): Maintained at or below 0.25%

- Koper (Cu): Limited to a maximum of 0.10%

- Mangaan (Mn): Typically below 0.10%

- Zink (Zn): Kept below 0.10%

Controlling these impurities prevents adverse effects such as reduced ductility, diminished corrosion resistance, or inconsistent mechanical behavior.

Tabel met chemische samenstelling

| Element | Typical Content (%) | Rol/impact |

|---|---|---|

| Aluminium | 97.2 | Base metal providing low density, Hoge geleidbaarheid |

| Magnesium | 2.2 - 2.8 | Strengthens through solid solution strengthening |

| Chroom | 0.15 - 0.35 | Enhances corrosion resistance and micro |

| Ijzer | ≤ 0.40 | Minimal amounts ensure no negative impact on ductility |

| Silicium | ≤ 0.25 | Maintains workability, minimizes brittleness |

| Koper | ≤ 0.10 | Kept low |

| Mangaan | ≤ 0.10 | Helps stabilize the alloy structure |

| Zink | ≤ 0.10 | Limited to prevent undesirable reactions |

2.2 Mechanische eigenschappen

Mechanical performance is the cornerstone of selecting 5052 aluminum sheet in engineering applications.

Key mechanical properties include tensile strength, levert kracht op, verlenging, and modulus of elasticity.

- Treksterkte: 5052 aluminum sheet typically exhibits an ultimate tensile strength around 228 MPA (ongeveer 33,000 psi) in hardened conditions such as H32 temper.

- Levert kracht op: The yield strength usually measures approximately 193 MPA (over 28,000 psi) in the H32 temper.

- Verlenging: The material demonstrates moderate ductility, with elongation values ranging from 8% naar 20% depending on the temper.

- Elasticiteitsmodulus: The modulus measures around 70 GPA, indicating good stiffness relative to its lightweight nature.

- Afschuifkracht: 5052 aluminum offers sufficient resistance to shear forces, an important factor during bending and forming operations.

Mechanische eigenschappentabel (Voorbeeldgegevens voor H32 Temper)

| Eigendom | Waarde (Metriek) | Waarde (Imperiaal) |

|---|---|---|

| Ultieme treksterkte | ~228 MPa | ~33,000 psi |

| Levert kracht op | ~193 MPa | ~ 28.000 psi |

| Verlenging | 8 - 12 | - |

| Elasticiteitsmodulus | ~70 GPa | ~10,200 ksi |

| Afschuifkracht | ~138 MPa | ~ 20.000 psi |

The process of cold working, which increases strength by inducing work hardening, significantly affects these mechanical parameters.

The alloy cannot be heat-treated to further increase strength, so the tempering process during cold working becomes paramount.

2.3 Fysieke eigenschappen

5052 aluminum sheet also boasts several favorable physical properties, making it versatile in a range of applications:

- Dikte: The density stands at approximately 2.68 g/cm³, which provides an excellent strength-to-weight ratio.

- Smeltpunt: The melting range lies between 607°C and 650°C, typical for aluminum alloys.

- Thermische geleidbaarheid: With a thermal conductivity of around 138 W/m · k, the material efficiently disperses heat, making it suitable for applications requiring heat exchange.

- Thermische expansiecoëfficiënt: The alloy exhibits a moderate coefficient of thermal expansion, rondom 23.7 x 10^–6/°C.

- Elektrische geleidbaarheid: The alloy retains good electrical conductivity, which remains important in many electronic and structural applications.

2.4 Omgevingsweerstand

5052 aluminum sheet stands out for its exceptional resistance to various environmental conditions:

- Corrosieweerstand: The natural formation of a protective aluminum oxide layer guards the underlying metal. Its chemistry, particularly the low copper content, further enhances its resistance to saltwater and acidic conditions.

- Vermoeidheidsterkte: The alloy also exhibits high fatigue strength, which is vital in applications subject to repetitive loading.

- Lasbaarheid en vormbaarheid: While excellent in corrosive environments, the alloy also maintains good weldability and formability in both static and dynamic use.

- Resistance to Extreme Conditions: In addition to high moisture and salt resistance, the alloy shows stability in both low and high temperature environments, ensuring durability over a long lifespan.

3. Productieproces van 5052 Aluminium blad

The production process for 5052 aluminum sheet employs several advanced, controlled methods to ensure the final product meets rigorous quality standards.

Manufacturers emphasize precision and efficiency through every step from raw material selection to final packaging.

3.1 Grondstofvoorbereiding

Manufacturers begin by selecting high-purity aluminum along with the necessary alloying elements (magnesium and chromium) based on strict quality criteria.

They source the best available materials and carry out initial testing to verify chemical compositions.

Quality assurance professionals run spectrometric tests and chemical analysis to ensure that impurities remain below the set thresholds.

3.2 Smelten- en gietproces

The next stage involves melting the pre-blended raw material in high-capacity furnaces, ensuring complete homogenization:

- Smeltend: Operators heat the materials to a temperature where all alloying elements dissolve uniformly into molten aluminum. This step ensures the chemical composition remains consistent.

- Gieten: The molten alloy flows into continuous casting molds or ingot molds. Continuous casting helps reduce gas entrapment and ensures a uniform grain structure in the resulting billets.

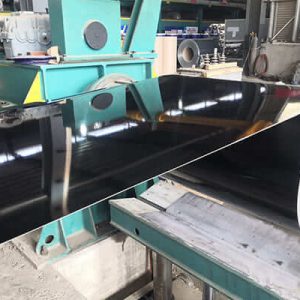

3.3 Heet rollend en ruw rollen

After casting, billets enter the hot rolling phase where the primary reduction in thickness occurs:

- Preheating: Billets reheat to optimal rolling temperatures (often above 400°C) to enhance ductility.

- Ruw rollend: Billets pass through a series of heavy-duty rollers that reduce thickness significantly while aligning the grain structure.

- Intermediate Measurements: Operators check dimensions and quality continuously to ensure uniform reduction.

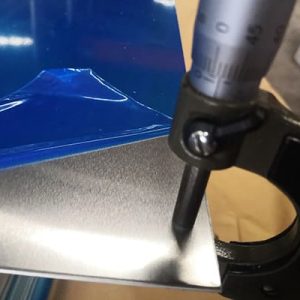

3.4 Koud rollend proces

Na hete rollen, Fabrikanten verschuiven naar koud rollen om de uiteindelijke meter te bereiken:

- Opeenvolgende passen: Het vel gaat door meerdere koude rollen die de dikte verder verminderen.

- Precisiebeheersing: Sluit monitoring van de dikte en oppervlakteafwerking; Aanpassingen komen in realtime op om een optimale consistentie te garanderen.

- Werkharden: Koud rollen verhoogt tegelijkertijd de kracht door werkhardend te zijn met behoud van ductiliteit.

3.5 Gloeiende behandeling

Koud gerolde vellen accumuleren interne stress die verlichting vereisen door gloeien:

- Warmtebehandeling: Operators verwarmen het koudgerolde vel tot een vooraf bepaalde temperatuur (Typisch rond 343 ° C tot 650 ° F) Om het herstel van de ductiliteit mogelijk te maken.

- Tijd vasthouden: Handhaaf de temperatuur voor een specifieke periode om uniforme stressverlichting te garanderen.

- Gecontroleerde koeling: Cooling occurs either in air or under controlled conditions to maintain the improved properties.

3.6 Rand snijden, Afsnijden, en spoelverpakking

The annealed sheet then undergoes final finishing processes:

- Edge Cutting and Trimming: Machines trim the edges to remove irregularities and achieve precise widths.

- Coil Formation: The sheet winds onto cores to form rolls, which facilitates handling, shipping, and subsequent fabrication.

- Verpakking: Manufacturers package the rolls securely, marking them with essential batch and specification information.

3.7 Belangrijkste controlepunten en kwaliteitsbewaking

Quality monitoring remains a continuous process throughout production:

- In-Line Measurements: Automated systems check thickness, breedte, and surface finish continuously.

- Oppervlakte -inspecties: Visual and optical inspection systems detect defects such as scratches, blisters, or contamination.

- Chemische analyse: Regular spectrometric testing verifies that the chemical composition remains within strict limits.

- Mechanisch testen: Trek, opbrengst, and elongation tests confirm that mechanical properties meet the required standards.

- Process Documentation: Operators document all process parameters to ensure full traceability and to support continuous improvement initiatives.

4. Veel voorkomende specificaties en producttypen

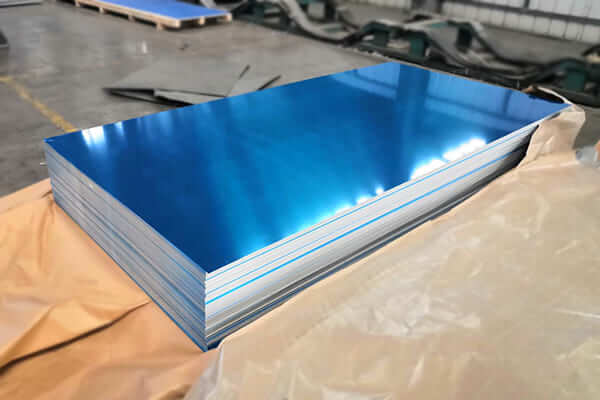

5052 aluminum sheet products vary widely in terms of thickness, breedte, temperen, and form factors.

Understanding the common specifications helps fabricators and engineers select the right product for their application.

4.1 Dikte en breedtebereik

Manufacturers produce 5052 aluminum sheet in a range of thicknesses and widths to cater to diverse industrial needs:

- Diktebereik: Typically ranges from as thin as 0.2 mm tot 6.0 mm or more. Applications in aerospace and electronics may require very thin gauge, while structural applications require thicker sheets.

- Breedtebereik: Sheets come in standard widths ranging from 500 mm to over 1600 mm. Custom widths may also be produced based on customer specifications.

Voorbeeldspecificatietabel

| Specificatie | Range/Standard Values |

|---|---|

| Dikte | 0 |

| Breedte | 500 mm - |

| Lengte (per roll) | 1000 m – 3000 M |

4.2 Verschillende tempertende toestanden

Tempering of 5052 aluminum sheet affects its mechanical properties significantly. The two main temper conditions are:

- O Temper (Annealed State): The sheet remains fully annealed. It features excellent formability and is very soft, which benefits applications where intricate forming is necessary.

- H Temper (Met stam geharde): The sheet undergoes cold working to increase its strength. Common sub-classifications include H32, H34, H36, and H38. Each level indicates a different hardness and strength profile.

- H32: Offers a balance of good strength and moderate formability.

- H34: Provides higher strength and hardness than H32, suitable for applications demanding enhanced structural performance.

- H36 and H38: Typically used for higher-performance applications where maximizing strength is critical.

4.3 Aangepaste producten en standaardproducten

Manufacturers offer both standard and customized products:

- Standaardproducten: Follow widely accepted industry dimensions and tempering conditions. They meet regular commercial needs.

- Aangepaste producten: Fabricators can tailor dimensions, temperen, edge finishes, and packaging to meet unique customer specifications. Customized orders often require close collaboration between the customer and the manufacturer to achieve optimal results.

5. Toepassing van 5052 Aluminium blad

5052 aluminum sheet finds widespread usage across numerous industries.

Its unique combination of strength, corrosieweerstand, and ease of fabrication makes it a versatile material.

5.1 Marine- en ruimtevaarttoepassingen

5052 aluminum sheet proves ideal in harsh environmental conditions:

- Mariene omgevingen: Its superb resistance to saltwater corrosion makes it essential for shipbuilding, offshore platforms, and marine equipment.

- Ruimtevaarttoepassingen: The alloy’s high strength-to-weight ratio supports its use in aircraft structures, fuselage panels, and aerospace components. Its fatigue resistance under cyclic loading makes it a preferred choice in aviation design.

5.2 Automotive en transport

5052 aluminum sheet also serves the automotive industry:

- Lichaamspanelen: The material’s formability and strength enable the manufacture of complex shapes required for car body panels and structural reinforcements.

- Brackets and Enclosures: Used in constructing brackets, warmteschilden, and other components due to its durability and lightweight nature.

- Transportation Equipment: It finds use in vehicle frames, truck bodies, and rail equipment, where reliability and cost-efficiency are paramount.

5.3 Bouw- en bouwgebruik

The construction sector benefits from the aesthetic and structural properties of 5052 aluminium blad:

- Architecturale bekleding: The material’s decorative finish and durability make it a popular choice for cladding and facade panels.

- Dakbedekking en gevelbekleding: Its lightweight nature and resistance to weathering suit it for roofing applications.

- HVAC Components: Use in ductwork and heat exchangers improves energy efficiency in buildings.

5.4 Industriële en elektronische toepassingen

Industries and electronics also rely on 5052 aluminium blad:

- Electronic Enclosures: The material’s good conductivity and corrosion resistance protect sensitive electronic components.

- Warmtewisselaars: Its high thermal conductivity allows efficient heat dissipation.

- Pressure Vessels and Tanks: Used in chemical processing and hydraulic systems thanks to robust mechanical properties and environmental resistance.

- Machined Components: Serves as a substrate for precision machined parts in a variety of industrial contexts.

5.5 Algemene verwerking en fabricage van plaatmetalen

5052 aluminum sheet proves versatile in general sheet metal operations:

- Forming and Bending: The alloy excels in cold-working processes. It bends without cracking, making it ideal for complex fabrications.

- Stamping and Drawing: Manufacturers use it to stamp or draw parts with intricate designs.

- Aangepaste fabricage: Industries favor 5052 aluminum for its ease of customization in components ranging from containers to custom brackets.

5.6 Speciale toepassingen

Certain niche applications leverage the unique properties of 5052 aluminium blad:

- Hernieuwbare energie: The material appears in solar panel frames and energy-efficient architectural projects.

- Medische hulpmiddelen: Its non-toxic, corrosion-resistant nature makes it suitable for medical equipment housings and instrument panels.

- Bewegwijzering en displays: Its smooth finish and high aesthetic value support the production of high-quality signs and nameplates.

- Industrial Automation: The alloy finds use in robotic enclosures and machine guarding due to its durability and ease of fabrication.

6. Normen, Testen, en certificering

Zorgen voor de kwaliteit van 5052 aluminum sheet relies on adherence to multiple standards and rigorous testing protocols.

Manufacturers and end users reference internationally recognized specifications to guarantee performance.

6.1 Relevante industriële normen en specificaties

5052 aluminum sheet complies with several standards set by organizations such as ASTM, ISO, BS, and EN.

Some commonly referenced standards include:

- ASTM B209: Specificeert de vereisten voor aluminium en aluminium-legering plaat en plaat.

- IN 485-2: European standard for aluminum sheet products.

- ISO 9001: Quality management systems that many manufacturers follow to ensure consistent quality.

- BS EN 573-3: Pertains to the chemical composition of aluminum alloys.

Manufacturers document compliance with these standards to demonstrate product reliability, ensuring that all material properties remain within permissible limits as established by these governing bodies.

6.2 Testmethoden en kwaliteitscertificering

Effective quality control of 5052 aluminum sheet employs a variety of test methods:

- Chemische analyse: Use of spectroscopy and other analytical methods confirms that chemical compositions meet established specifications.

- Mechanisch testen: Treksterkte, levert kracht op, verlenging, and other mechanical properties receive validation through standardized tests (Bijv., according to ASTM B209).

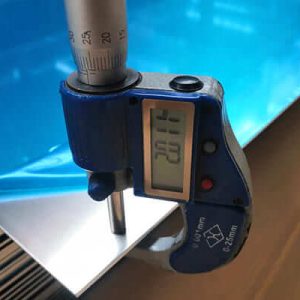

- Dimensionale metingen: Laser gauges and ultrasonic thickness testers ensure precise thickness and width.

- Oppervlakte -inspectie: Visual and automated optical inspections check for surface defects, ensuring that the sheet meets high-quality standards.

- Corrosietesten: Accelerated salt spray and immersion tests predict long-term environmental resistance.

- Certificering: Manufacturers secure quality certifications such as ISO 9001 and others from independent laboratories to validate performance. They also provide traceability documentation and batch test reports for customer assurance.

Voorbeeld Quality Certification Checklist:

- Chemical Composition Report

- Tensile and Yield Test Data

- Dimensional Tolerance Records

- Surface Quality Inspection Reports

- Corrosion Resistance Test Results

- ISO 9001 Certification Documentation

7. Veelgestelde vragen (FAQ)

This section answers common queries and provides clarifications regarding 5052 aluminium blad.

7.1 Hoe is 5052 Aluminium blad anders dan andere aluminium vellen?

5052 aluminum sheet differs primarily in its alloy composition.

It uses magnesium as the principal alloying element and includes trace amounts of chromium.

This composition delivers an excellent balance of strength, corrosieweerstand, en vormbaarheid, setting it apart from purer grades (leuk vinden 1100) or heat-treatable alloys (leuk vinden 6061).

Its ability to undergo cold work without further heat treatment marks its unique position in the 5000 serie.

7.2 Hoe is de hygiënische veiligheid van 5052 Aluminium blad gegarandeerd?

Manufacturers guarantee the hygienic safety of 5052 aluminum sheet by:

- Strict Raw Material Selection: Sourcing high-purity aluminum and controlling impurity levels.

- Clean Production Environment: Maintaining contamination-free production areas.

- Oppervlaktebehandeling: Ensuring the sheet remains free from contaminants through surface cleaning and protective oxide layer formation.

- Testing and Certification: Conducting frequent tests and securing certifications (Bijv., FDA approval for certain applications) to assure product safety in applications such as food packaging and medical devices.

7.3 Welke temperen van omstandigheden van 5052 Aluminium blad is geschikt voor specifieke toepassingen?

The temper of 5052 aluminum sheet influences its mechanical properties:

- O Temper (Gegloeid): Ideal for applications requiring maximum formability, where complex shapes and bending are necessary.

- H32 Temper: Offers a balanced mix of strength and ductility, perfect for fabricated parts that require moderate strength without excessive stiffness.

- H34/H36/H38 Temper: Provide higher strength and are used when increased load-bearing capacity is needed but might come with reduced formability. Select the temper based on your application’s specific mechanical stress and forming requirements.

7.4 Hoe regelen fabrikanten de dikte -toleranties en oppervlaktekwaliteit tijdens de productie?

Manufacturers implement robust quality control measures:

- Real-Time Monitoring: Automated in-line systems measure thickness and width continuously.

- Precision Equipment: Use of laser or ultrasonic gauges ensures precise and uniform dimensions.

- Regular Inspections: Visual and optical inspections detect surface defects early.

- Process Adjustments: Operators adjust rolling pressure, speed, and annealing conditions immediately if deviations occur.

- Quality Documentation: Each batch gets detailed records to validate compliance with tolerance specifications.

7.5 How to Evaluate the Environmental Impact and Recyclability of 5052 Aluminium blad?

Evaluating the environmental benefits includes:

- Recycllabaliteit: Aluminum recycles efficiently with minimal degradation in properties. Recycling aluminum requires substantially less energy than primary production.

- Life Cycle Analysis (LCA): LCA studies detail the total energy consumption, greenhouse gas emissions, and material usage from production to disposal.

- Certifications and Environmental Audits: Independent environmental audits and certifications (Bijv., ISO 14001) validate sustainable practices.

- Circulaire economie profiteert: Evaluate how the material integrates into sustainable cycles, reducing waste and supporting eco-friendly practices.

- Energy Savings Metrics: Compare energy consumption between primary production and recycling to underscore the environmental advantages.

8. Samenvatting

In this comprehensive article, we examined 5052 aluminum sheet from multiple perspectives.

We started by defining the material and highlighting its significance in industries ranging from marine and aerospace to automotive, bouw, en industriële toepassingen.

Artical delved into the alloy’s composition, discussing its main components (high-purity aluminum), auxiliary elements (magnesium and chromium), and trace impurities that manufacturers rigorously control.

We outlined the key mechanical and physical properties—including tensile strength, levert kracht op, verlenging, density, thermische geleidbaarheid, and corrosion resistance—that make 5052 aluminum sheet an attractive choice for engineers and designers.

The article then provided a detailed overview of the manufacturing process.

We covered raw material preparation, melting and casting, hot and cold rolling, glans, edge trimming, and coil packaging.

Emphasis was placed on the key control points and quality monitoring protocols that ensure dimensional and chemical consistency.

Verder, we reviewed common specifications including thickness and width ranges, tempering states (O, H32, H34, enz.), and the availability of both standardized and custom products.

The discussion on applications demonstrated how the unique properties of 5052 aluminum sheet serve marine, ruimtevaart, automotive, building, industrieel, and even special niche applications where reliability and sustainability matter.

More products about Langhe: https://langhe-alu.com/products/

Gerelateerde producten

Gerelateerde producten

-

Aluminium plaatplaat

5086 Aluminium blad

0 uit 5¥3,750.00Ontgrendel de technische voordelen van 5086 Aluminium blad. Diepgaande analyse van de duurzaamheid, Uitstekende lasbaarheid, en hoogste corrosiebespullende voor kritische structuren en barre omstandigheden.

-

Aluminium plaatplaat

5083 Aluminium blad

0 uit 5¥3,780.00Ontdek een hoge prestatie 5083 aluminium blad, Ontwikkeld voor scheepsbouw, automotive, en structurele toepassingen. Superieure corrosieweerstand, lasbaarheid, en duurzaamheid.

-

Aluminium plaatplaat

1070 Aluminium plaatplaat

0 uit 5¥3,300.00Verken de chemische samenstelling, corrosieweerstand, en productieproces van 1070 aluminium blad. Kijk waarom ingenieurs het kiezen voor busbars, Warmtewisselaars, en decoratieve panelen.

-

Aluminium plaatplaat

5005 Aluminium blad

0 uit 5¥3,680.00Ontgrendel het potentieel van 5005 aluminium blad, Ideaal voor superieure geanodiseerde afwerkingen in architectuur, decoratief, en elektrisch gebruik. Leer de voordelen ervan en waarom het opvalt.

-

Aluminium plaatplaat

3004 Aluminium blad

0 uit 5¥3,860.00De 3004 aluminium blad van Langhe Aluminium Co. is een veelzijdig materiaal dat bekend staat om zijn corrosieweerstand, Matige kracht, en uitstekende vormbaarheid. Voornamelijk samengesteld uit aluminium en mangaan, het is…

-

Aluminium plaatplaat

3003 Aluminium plaat

0 uit 5¥3,350.003003 aluminium plaat: corrosiebestendig, vormbaar, Ideaal voor tanks, dakbedekking & vervoer. Beschikbaar in H14/H24/O -temperatuur, Dikte 0,2-150 mm. Kies Mill, in reliëf of geschilderde afwerkingen.

-

Aluminium plaatplaat

6061 Aluminium blad

0 uit 5¥5,450.006061 Aluminium plaat geleverd door Langhe-Alu is een populair industrieel materiaal. Met zijn uitstekende uitgebreide prestaties, Het wordt veel gebruikt in de ruimtevaart, machineproductie, scheepsbouw, Automotive -industrie en architecturale decoratie.

-

Aluminium plaatplaat

1100 Aluminium blad

0 uit 5¥3,482.001100 Aluminium blad Uitstekende corrosieweerstand, Vormbaarheid, en geleidbaarheid maken het ideaal voor toepassingen in chemische apparatuur, voedselverwerking, en architecturale projecten. Leer waarom het een topkeuze is voor industrieel…

-

Aluminium plaatplaat

5754 Aluminium blad

0 uit 5¥5,208.005754 Aluminiumplaat wordt veel gebruikt vanwege de uitstekende sterkte-gewichtsverhouding, Corrosieweerstand en machinaliteit. Zoals: ruimtevaart, auto, schip, bouwtoepassingen, Landing van het drukvat, enz.

-

Aluminium plaatplaat

1060 Aluminium blad

0 uit 5¥3,468.001060 aluminium plaat is een gemeenschappelijk lichtgewicht materiaal dat behoort tot de 1000 serie aluminium legering. Het is populair op de markt vanwege de lage prijs, Sterke corrosieweerstand en…