1. 5052 Aluminum Sheet Overview

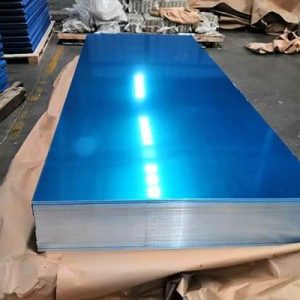

5052 aluminum sheet represents one of the most widely used aluminum alloys in sheet form.

This material enjoys a strong reputation among engineers and fabricators alike due to its superb balance of strength, Formovateľnosť, a vynikajúca odolnosť proti korózii.

1.1 Definícia 5052 Hliníkový list

5052 aluminum sheet defines a non-heat-treatable alloy within the 5000 series that uses magnesium as the primary alloying element along with a trace addition of chromium.

Manufacturers produce 5052 aluminum sheet by starting with high-purity aluminum and blending in the alloying elements to achieve an optimal balance.

The alloy typically contains approximately 97.2%–98.9% aluminum, with magnesium levels ranging between 2.2% a 2.8% and chromium levels from 0.15% do 0.35%.

These percentages produce a material with improved mechanical strength, enhanced fatigue resistance, and an outstanding resistance to corrosive environments.

1.2 Overview of Its Importance in Various Industries

5052 aluminum sheet serves a critical role in many industries.

Its excellent resistance to corrosion, especially in marine atmospheres, along with its exceptional formability, make it indispensable in both traditional and advanced applications.

Many industries benefit from 5052 aluminum sheet in the following ways:

- Námorné aplikácie: The alloy withstands saltwater corrosion, making it a top choice for shipbuilding, morské štruktúry, and offshore equipment.

- Aerospace and Transportation: Lightweight design paired with high fatigue resistance and good weldability supports its use in aerospace components, aircraft skins, and vehicle chassis.

- Automobilový priemysel: Engineers favor 5052 for body panels, zátvorky, and other structural components due to its strength-to-weight ratio.

- Výstavba: In architectural applications, the material exhibits durability and aesthetic appeal when used in cladding, strešná strecha, a dekoratívne panely.

- Industrial and Electronic Sectors: Its excellent mechanical properties suit the production of pressure vessels, elektronické kryty, and heat exchangers.

- General Sheet Metal Fabrication: Its ease of cold working enables manufacturers to produce precision parts such as containers, potrubie, and customized fabricated assemblies.

The alloy’s versatility has led to robust global demand, where its performance characteristics deliver both economic and technical benefits.

Industries choose 5052 aluminum sheet when they require a material that meets strict durability, safety, and sustainability standards.

2. Material Properties and Performance Parameters

A deep understanding of the material properties and performance parameters of 5052 aluminum sheet enables its optimal application.

This section explains the alloy classification, kompozícia, and the key mechanical, physical, and environmental properties that define this material.

2.1 Alloy Classification and Composition

5052 belongs to the 5xxx series aluminum alloys that primarily use magnesium as the key alloying element.

Its composition design helps achieve a well-balanced combination of strength, ťažkosť, a odolnosť proti korózii.

2.1.1 Hlavné komponenty

The primary component of 5052 aluminum sheet is high-purity aluminum, which forms the matrix.

Zvyčajne, the aluminum content accounts for approximately 97.2% do 98.9% of the alloy.

This high aluminum base provides excellent conductivity, low density, and inherent malleability.

2.1.2 Pomocné prvky

Magnesium plays a crucial role in enhancing the material’s strength through solid solution strengthening.

V 5052 hliníkový list, the magnesium content usually ranges between 2.2% a 2.8%.

The small addition of chromium—approximately 0.15% to 0.35%—further contributes to improved corrosion resistance and stabilization of the microstructure.

2.1.3 Stopové prvky a nečistoty

To maintain consistency and high performance, manufacturers strictly control the levels of impurities and trace elements.

The common controlled elements include:

- Žehlička (FE): Kept below 0.40%

- Kremík (A): Maintained at or below 0.25%

- Meď (Cu): Limited to a maximum of 0.10%

- Mangán (Mn): Typically below 0.10%

- Zinok (Zn): Kept below 0.10%

Controlling these impurities prevents adverse effects such as reduced ductility, diminished corrosion resistance, or inconsistent mechanical behavior.

Stôl chemického zloženia

| Prvok | Typical Content (%) | Role/Impact |

|---|---|---|

| Hliník | 97.2 | Base metal providing low density, vysoká vodivosť |

| Horčík | 2.2 - 2.8 | Strengthens through solid solution strengthening |

| Chróm | 0.15 - 0.35 | Enhances corrosion resistance and micro |

| Žehlička | ≤ 0.40 | Minimal amounts ensure no negative impact on ductility |

| Kremík | ≤ 0.25 | Maintains workability, minimizes brittleness |

| Meď | ≤ 0.10 | Kept low |

| Mangán | ≤ 0.10 | Helps stabilize the alloy structure |

| Zinok | ≤ 0.10 | Limited to prevent undesirable reactions |

2.2 Mechanické vlastnosti

Mechanical performance is the cornerstone of selecting 5052 aluminum sheet in engineering applications.

Key mechanical properties include tensile strength, výnosová sila, predĺženie, and modulus of elasticity.

- Pevnosť v ťahu: 5052 aluminum sheet typically exhibits an ultimate tensile strength around 228 MPA (približne 33,000 psi) in hardened conditions such as H32 temper.

- Výnosová sila: The yield strength usually measures approximately 193 MPA (o 28,000 psi) in the H32 temper.

- Predĺženie: The material demonstrates moderate ductility, with elongation values ranging from 8% do 20% depending on the temper.

- Modul elasticity: The modulus measures around 70 GPA, indicating good stiffness relative to its lightweight nature.

- Strih: 5052 aluminum offers sufficient resistance to shear forces, an important factor during bending and forming operations.

Mechanical Properties Table (Example Data for H32 Temper)

| Majetok | Hodnota (Metrika) | Hodnota (Cisársky) |

|---|---|---|

| Konečná pevnosť v ťahu | ~228 MPa | ~33,000 psi |

| Výnosová sila | ~193 MPa | ~ 28 000 psi |

| Predĺženie | 8 - 12 | - |

| Modul elasticity | ~70 GPa | ~10,200 ksi |

| Strih | ~138 MPa | ~ 20 000 psi |

The process of cold working, which increases strength by inducing work hardening, significantly affects these mechanical parameters.

The alloy cannot be heat-treated to further increase strength, so the tempering process during cold working becomes paramount.

2.3 Fyzické vlastnosti

5052 aluminum sheet also boasts several favorable physical properties, making it versatile in a range of applications:

- Hustota: The density stands at approximately 2.68 g/cm³, which provides an excellent strength-to-weight ratio.

- Miesto topenia: The melting range lies between 607°C and 650°C, typical for aluminum alloys.

- Tepelná vodivosť: With a thermal conductivity of around 138 W/m · k, the material efficiently disperses heat, making it suitable for applications requiring heat exchange.

- Koeficient tepelnej expanzie: The alloy exhibits a moderate coefficient of thermal expansion, okolo 23.7 x 10^–6/°C.

- Elektrická vodivosť: The alloy retains good electrical conductivity, which remains important in many electronic and structural applications.

2.4 Environmental Resistance

5052 aluminum sheet stands out for its exceptional resistance to various environmental conditions:

- Odpor: The natural formation of a protective aluminum oxide layer guards the underlying metal. Its chemistry, particularly the low copper content, further enhances its resistance to saltwater and acidic conditions.

- Únava: The alloy also exhibits high fatigue strength, which is vital in applications subject to repetitive loading.

- Zvárateľnosť: While excellent in corrosive environments, the alloy also maintains good weldability and formability in both static and dynamic use.

- Resistance to Extreme Conditions: In addition to high moisture and salt resistance, the alloy shows stability in both low and high temperature environments, ensuring durability over a long lifespan.

3. Výrobný proces 5052 Hliníkový list

The production process for 5052 aluminum sheet employs several advanced, controlled methods to ensure the final product meets rigorous quality standards.

Manufacturers emphasize precision and efficiency through every step from raw material selection to final packaging.

3.1 Príprava surovín

Manufacturers begin by selecting high-purity aluminum along with the necessary alloying elements (magnesium and chromium) based on strict quality criteria.

They source the best available materials and carry out initial testing to verify chemical compositions.

Quality assurance professionals run spectrometric tests and chemical analysis to ensure that impurities remain below the set thresholds.

3.2 Melting and Casting Process

The next stage involves melting the pre-blended raw material in high-capacity furnaces, ensuring complete homogenization:

- Taviace sa: Operators heat the materials to a temperature where all alloying elements dissolve uniformly into molten aluminum. This step ensures the chemical composition remains consistent.

- Odlievanie: The molten alloy flows into continuous casting molds or ingot molds. Continuous casting helps reduce gas entrapment and ensures a uniform grain structure in the resulting billets.

3.3 Horúce a drsné valcovanie

After casting, billets enter the hot rolling phase where the primary reduction in thickness occurs:

- Preheating: Billets reheat to optimal rolling temperatures (often above 400°C) to enhance ductility.

- Drsné valcovanie: Billets pass through a series of heavy-duty rollers that reduce thickness significantly while aligning the grain structure.

- Intermediate Measurements: Operators check dimensions and quality continuously to ensure uniform reduction.

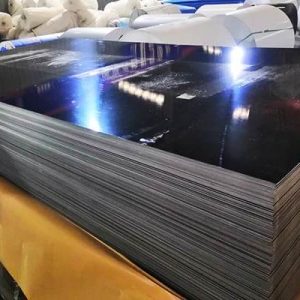

3.4 Proces valcovania

Po horúcom valcovaní, manufacturers shift to cold rolling to achieve the final gauge:

- Sequential Passes: The sheet passes through multiple cold rollers that incrementally reduce thickness further.

- Precision Control: Close monitoring of thickness and surface finish; adjustments occur in real time to ensure optimal consistency.

- Tvrdenie práce: Cold rolling simultaneously increases strength through work-hardening while preserving ductility.

3.5 Liečba žíhania

Cold-rolled sheets accumulate internal stresses that require relief through annealing:

- Tepelné spracovanie: Operators heat the cold-rolled sheet to a predetermined temperature (typically around 343°C to 650°F) to allow recovery of ductility.

- Holding Time: Maintain the temperature for a specific period to ensure uniform stress relief.

- Controlled Cooling: Cooling occurs either in air or under controlled conditions to maintain the improved properties.

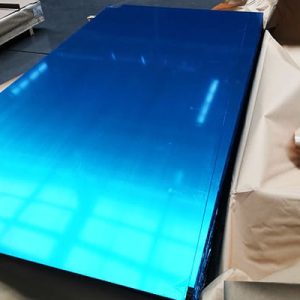

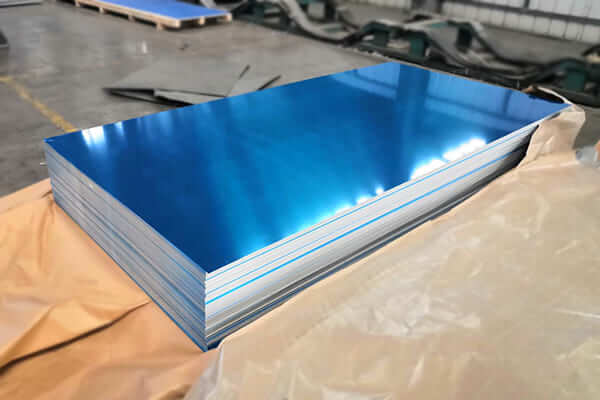

3.6 Edge Cutting, Orezávanie, and Coil Packaging

The annealed sheet then undergoes final finishing processes:

- Edge Cutting and Trimming: Machines trim the edges to remove irregularities and achieve precise widths.

- Coil Formation: The sheet winds onto cores to form rolls, which facilitates handling, shipping, and subsequent fabrication.

- Balenie: Manufacturers package the rolls securely, marking them with essential batch and specification information.

3.7 Key Control Points and Quality Monitoring

Quality monitoring remains a continuous process throughout production:

- In-Line Measurements: Automated systems check thickness, šírka, and surface finish continuously.

- Povrchové inšpekcie: Visual and optical inspection systems detect defects such as scratches, blisters, or contamination.

- Chemická analýza: Regular spectrometric testing verifies that the chemical composition remains within strict limits.

- Mechanické testovanie: Ťah, výnos, and elongation tests confirm that mechanical properties meet the required standards.

- Process Documentation: Operators document all process parameters to ensure full traceability and to support continuous improvement initiatives.

4. Bežné špecifikácie a typy výrobkov

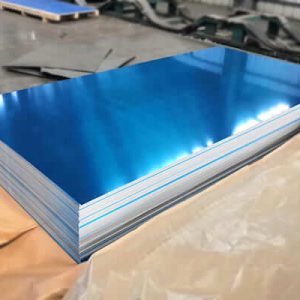

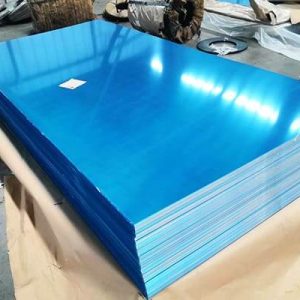

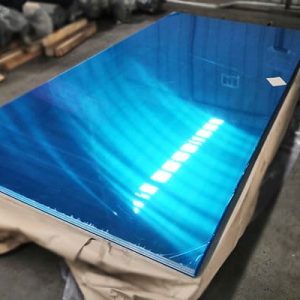

5052 aluminum sheet products vary widely in terms of thickness, šírka, temperovanie, and form factors.

Understanding the common specifications helps fabricators and engineers select the right product for their application.

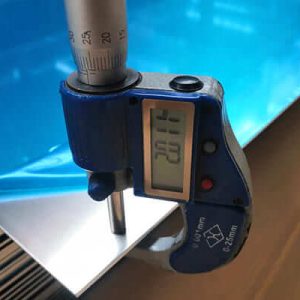

4.1 Rozsah hrúbky a šírky

Manufacturers produce 5052 aluminum sheet in a range of thicknesses and widths to cater to diverse industrial needs:

- Rozsah hrúbky: Typically ranges from as thin as 0.2 mm až 6.0 mm or more. Applications in aerospace and electronics may require very thin gauge, while structural applications require thicker sheets.

- Rozsah šírky: Sheets come in standard widths ranging from 500 mm to over 1600 mm. Custom widths may also be produced based on customer specifications.

Example Specification Table

| Špecifikácia | Range/Standard Values |

|---|---|

| Hrúbka | 0 |

| Šírka | 500 mm - |

| Dĺžka (per roll) | 1000 m – 3000 m |

4.2 Rôzne temperujúce stavy

Tempering of 5052 aluminum sheet affects its mechanical properties significantly. The two main temper conditions are:

- O (Annealed State): The sheet remains fully annealed. It features excellent formability and is very soft, which benefits applications where intricate forming is necessary.

- H Temper (Tvrdý): The sheet undergoes cold working to increase its strength. Common sub-classifications include H32, H34, H36, and H38. Each level indicates a different hardness and strength profile.

- H32: Offers a balance of good strength and moderate formability.

- H34: Provides higher strength and hardness than H32, suitable for applications demanding enhanced structural performance.

- H36 and H38: Typically used for higher-performance applications where maximizing strength is critical.

4.3 Customized Products and Standard Products

Manufacturers offer both standard and customized products:

- Štandardné výrobky: Follow widely accepted industry dimensions and tempering conditions. They meet regular commercial needs.

- Prispôsobené výrobky: Fabricators can tailor dimensions, temperovanie, edge finishes, and packaging to meet unique customer specifications. Customized orders often require close collaboration between the customer and the manufacturer to achieve optimal results.

5. Application of 5052 Hliníkový list

5052 aluminum sheet finds widespread usage across numerous industries.

Its unique combination of strength, odpor, and ease of fabrication makes it a versatile material.

5.1 Marine and Aerospace Applications

5052 aluminum sheet proves ideal in harsh environmental conditions:

- Morské prostredie: Its superb resistance to saltwater corrosion makes it essential for shipbuilding, offshore platforms, and marine equipment.

- Letecké aplikácie: The alloy’s high strength-to-weight ratio supports its use in aircraft structures, trupové panely, and aerospace components. Its fatigue resistance under cyclic loading makes it a preferred choice in aviation design.

5.2 Automobilový priemysel

5052 aluminum sheet also serves the automotive industry:

- Telesné panely: The material’s formability and strength enable the manufacture of complex shapes required for car body panels and structural reinforcements.

- Brackets and Enclosures: Used in constructing brackets, tepelné štíty, and other components due to its durability and lightweight nature.

- Prepravné zariadenie: It finds use in vehicle frames, truck bodies, and rail equipment, where reliability and cost-efficiency are paramount.

5.3 Building and Construction Uses

The construction sector benefits from the aesthetic and structural properties of 5052 hliníkový list:

- Architektonické opláštenie: The material’s decorative finish and durability make it a popular choice for cladding and facade panels.

- Zastrešovanie: Its lightweight nature and resistance to weathering suit it for roofing applications.

- HVAC Components: Use in ductwork and heat exchangers improves energy efficiency in buildings.

5.4 Priemyselné a elektronické aplikácie

Industries and electronics also rely on 5052 hliníkový list:

- Electronic Enclosures: The material’s good conductivity and corrosion resistance protect sensitive electronic components.

- Výmenník tepla: Its high thermal conductivity allows efficient heat dissipation.

- Pressure Vessels and Tanks: Used in chemical processing and hydraulic systems thanks to robust mechanical properties and environmental resistance.

- Machined Components: Serves as a substrate for precision machined parts in a variety of industrial contexts.

5.5 General Sheet Metal Processing and Fabrication

5052 aluminum sheet proves versatile in general sheet metal operations:

- Forming and Bending: The alloy excels in cold-working processes. It bends without cracking, making it ideal for complex fabrications.

- Stamping and Drawing: Manufacturers use it to stamp or draw parts with intricate designs.

- Vlastná výroba: Industries favor 5052 aluminum for its ease of customization in components ranging from containers to custom brackets.

5.6 Špeciálne aplikácie

Certain niche applications leverage the unique properties of 5052 hliníkový list:

- Renewable Energy: The material appears in solar panel frames and energy-efficient architectural projects.

- Medical Devices: Its non-toxic, corrosion-resistant nature makes it suitable for medical equipment housings and instrument panels.

- Značenie a displeje: Its smooth finish and high aesthetic value support the production of high-quality signs and nameplates.

- Industrial Automation: The alloy finds use in robotic enclosures and machine guarding due to its durability and ease of fabrication.

6. Štandardy, Testovanie, a certifikácia

Zabezpečenie kvality 5052 aluminum sheet relies on adherence to multiple standards and rigorous testing protocols.

Manufacturers and end users reference internationally recognized specifications to guarantee performance.

6.1 Príslušné priemyselné normy a špecifikácie

5052 aluminum sheet complies with several standards set by organizations such as ASTM, ISO, BS, a a a.

Some commonly referenced standards include:

- ASTM B209: Určuje požiadavky na plech a dosku z hliníka a hliníka.

- V 485-2: European standard for aluminum sheet products.

- ISO 9001: Quality management systems that many manufacturers follow to ensure consistent quality.

- BS EN 573-3: Pertains to the chemical composition of aluminum alloys.

Manufacturers document compliance with these standards to demonstrate product reliability, ensuring that all material properties remain within permissible limits as established by these governing bodies.

6.2 Test Methods and Quality Certification

Effective quality control of 5052 aluminum sheet employs a variety of test methods:

- Chemická analýza: Use of spectroscopy and other analytical methods confirms that chemical compositions meet established specifications.

- Mechanické testovanie: Tensile strength, výnosová sila, predĺženie, and other mechanical properties receive validation through standardized tests (Napr., according to ASTM B209).

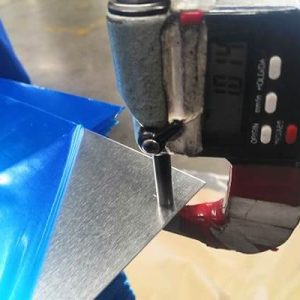

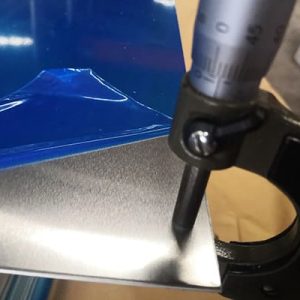

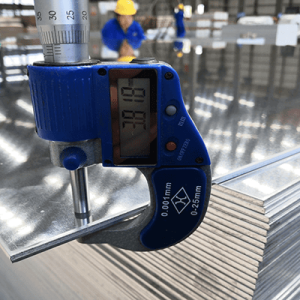

- Rozmerové merania: Laser gauges and ultrasonic thickness testers ensure precise thickness and width.

- Preskúmanie povrchu: Visual and automated optical inspections check for surface defects, ensuring that the sheet meets high-quality standards.

- Testovanie korózie: Accelerated salt spray and immersion tests predict long-term environmental resistance.

- Osvedčenie: Manufacturers secure quality certifications such as ISO 9001 and others from independent laboratories to validate performance. They also provide traceability documentation and batch test reports for customer assurance.

Example Quality Certification Checklist:

- Chemical Composition Report

- Tensile and Yield Test Data

- Dimensional Tolerance Records

- Surface Quality Inspection Reports

- Corrosion Resistance Test Results

- ISO 9001 Certification Documentation

7. Často kladené otázky (Často)

This section answers common queries and provides clarifications regarding 5052 hliníkový list.

7.1 How is 5052 Aluminum Sheet Different from Other Aluminum Sheets?

5052 aluminum sheet differs primarily in its alloy composition.

It uses magnesium as the principal alloying element and includes trace amounts of chromium.

This composition delivers an excellent balance of strength, odpor, a formovateľnosť, setting it apart from purer grades (ako 1100) or heat-treatable alloys (ako 6061).

Its ability to undergo cold work without further heat treatment marks its unique position in the 5000 séria.

7.2 How is the Hygienic Safety of 5052 Aluminum Sheet Guaranteed?

Manufacturers guarantee the hygienic safety of 5052 aluminum sheet by:

- Strict Raw Material Selection: Sourcing high-purity aluminum and controlling impurity levels.

- Clean Production Environment: Maintaining contamination-free production areas.

- Ošetrenie povrchom: Ensuring the sheet remains free from contaminants through surface cleaning and protective oxide layer formation.

- Testing and Certification: Conducting frequent tests and securing certifications (Napr., FDA approval for certain applications) to assure product safety in applications such as food packaging and medical devices.

7.3 Which Tempering Conditions of 5052 Aluminum Sheet Are Suitable for Specific Applications?

The temper of 5052 aluminum sheet influences its mechanical properties:

- O (Žíhaný): Ideal for applications requiring maximum formability, where complex shapes and bending are necessary.

- H32 teplota: Offers a balanced mix of strength and ductility, perfect for fabricated parts that require moderate strength without excessive stiffness.

- H34/H36/H38 Temper: Provide higher strength and are used when increased load-bearing capacity is needed but might come with reduced formability. Select the temper based on your application’s specific mechanical stress and forming requirements.

7.4 How Do Manufacturers Control Thickness Tolerances and Surface Quality During Production?

Manufacturers implement robust quality control measures:

- Real-Time Monitoring: Automated in-line systems measure thickness and width continuously.

- Precision Equipment: Use of laser or ultrasonic gauges ensures precise and uniform dimensions.

- Regular Inspections: Visual and optical inspections detect surface defects early.

- Process Adjustments: Operators adjust rolling pressure, speed, and annealing conditions immediately if deviations occur.

- Quality Documentation: Each batch gets detailed records to validate compliance with tolerance specifications.

7.5 How to Evaluate the Environmental Impact and Recyclability of 5052 Hliníkový list?

Evaluating the environmental benefits includes:

- Recyklatalita: Aluminum recycles efficiently with minimal degradation in properties. Recycling aluminum requires substantially less energy than primary production.

- Life Cycle Analysis (LCA): LCA studies detail the total energy consumption, greenhouse gas emissions, and material usage from production to disposal.

- Certifications and Environmental Audits: Independent environmental audits and certifications (Napr., ISO 14001) validate sustainable practices.

- Prínosy obehovej ekonomiky: Evaluate how the material integrates into sustainable cycles, reducing waste and supporting eco-friendly practices.

- Energy Savings Metrics: Compare energy consumption between primary production and recycling to underscore the environmental advantages.

8. Zhrnutie

In this comprehensive article, we examined 5052 aluminum sheet from multiple perspectives.

We started by defining the material and highlighting its significance in industries ranging from marine and aerospace to automotive, výstavba, a priemyselné aplikácie.

Artical delved into the alloy’s composition, discussing its main components (high-purity aluminum), auxiliary elements (magnesium and chromium), and trace impurities that manufacturers rigorously control.

We outlined the key mechanical and physical properties—including tensile strength, výnosová sila, predĺženie, density, tepelná vodivosť, and corrosion resistance—that make 5052 aluminum sheet an attractive choice for engineers and designers.

The article then provided a detailed overview of the manufacturing process.

We covered raw material preparation, melting and casting, hot and cold rolling, žíhanie, edge trimming, and coil packaging.

Emphasis was placed on the key control points and quality monitoring protocols that ensure dimensional and chemical consistency.

Ďalej, we reviewed common specifications including thickness and width ranges, tempering states (O, H32, H34, atď.), and the availability of both standardized and custom products.

The discussion on applications demonstrated how the unique properties of 5052 aluminum sheet serve marine, letectvo, automobilový, building, priemyselný, and even special niche applications where reliability and sustainability matter.

More products about Langhe: https://langhe-alu.com/products/

Súvisiace výrobky

Súvisiace výrobky

-

Hliníkový plech

6063 Hliníkový list: Achieve Flawless Finishes

0 z 5¥5,800.00Known for its exceptional surface quality and superior anodizing response, 6063 Aluminum Sheet is the ideal material for architectural trim, dekoratívne komponenty, and applications where aesthetics are paramount.

-

Hliníkový plech

5454 Hliníkový plech

0 z 5¥3,600.00Zvoliť si 5454 Hliníkový plech pre ľahkú pevnosť v morských palubách, chemické plavidlá, a tlakové nádoby. Preukázaná spoľahlivosť, ľahká výroba.

-

Hliníkový plech

5182 Hliníkový plech

0 z 5¥3,650.00Vyberte vysokú výkonnosť 5182 hliníkový plech pre výnimočnú formovateľnosť, zvárateľnosť, a trvalá trvanlivosť v mori, automobilový, a priemyselné použitie.

-

Hliníkový plech

5086 Hliníkový list

0 z 5¥3,750.00Odomknite technické výhody 5086 Hliníkový list. Hĺbková analýza jeho trvanlivosti, vynikajúca zvárateľnosť, a najvyššia korózia, ktorá sa týka kritických štruktúr a tvrdých podmienok.

-

Hliníkový plech

5083 Hliníkový list

0 z 5¥3,780.00Objaviť vysokovýkonné 5083 hliníkový list, skonštruovaný na stavbu lodí, automobilový, a štrukturálne aplikácie. Vynikajúca odolnosť proti korózii, zvárateľnosť, a trvanlivosť.

-

Hliníkový plech

Hliníkový panel

0 z 5¥4,500.00Objavte, ako voštinový hliníkový panel dodáva vynikajúcu tuhosť v ohybe, tepelná izolácia, a požiarna bezpečnosť - všetko pri 70% menšia hmotnosť ako tuhý kov. Ideálne na to, aby ste sa dostali, letectvo, a priemyselný dizajn.

-

Hliníkový plech

3003 Hliníková doska

0 z 5¥3,350.003003 hliníková doska: odolný voči korózii, vytvorený, Ideálne pre tanky, strešná strecha & preprava. K dispozícii v pokušeniach H14/H24/O, Hrúbka 0,2-150 mm. Vyberte mlyn, vyrazené alebo maľované povrchové úpravy.

-

Hliníkový plech

5754 Hliníkový list

0 z 5¥5,208.005754 Hliníková doska sa široko používa vďaka svojmu vynikajúcemu pomeru pevnosti k hmotnosti, Odolnosť proti korózii a machináovateľnosť. Ako: letectvo, automobil, odoslať, stavebné aplikácie, pristátie, tam.

-

Hliníkový plech

1060 Hliníkový list

0 z 5¥3,468.001060 hliníková doska je bežný ľahký materiál patriaci k 1000 hliníková zliatina. Je populárny na trhu kvôli svojej nízkej cene, silný odolnosť proti korózii a…

-

Hliníkový plech

2219 Hliníkový list T37

0 z 5¥10,714.002219 Hliníkový list T37 je v hliníkovom liste s vysokou pevnou zliatinou v 2000 hliníková zliatina, ktorý sa široko používa v leteckom priestore, morské inžinierstvo, prostredie s vysokou teplotou a ďalšie polia.