What is 2219 T37 Aluminum Sheet?

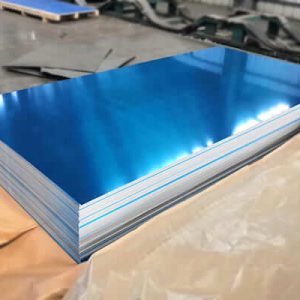

2219 T37 aluminum sheet is a high-strength aluminum-copper alloy known for its excellent mechanical properties, corrosion resistance, and thermal stability.

This alloy is widely used in industries requiring strong, lightweight, and durable materials, particularly in aerospace and structural applications.

The T37 temper designation indicates a specific treatment that enhances its mechanical properties and workability.

Chemical composition of 2219 aluminum

| Element | Al | Cu | Mn | Fe | Mg | Si | Ti | V | Zr | Other | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | Balance | 5.8 – 6.8 | 0.2 – 0.4 | ≤ 0.30 | ≤ 0.02 | ≤ 0.20 | 0.02 – 0.10 | 0.05 – 0.15 | 0.10 – 0.25 | ≤ 0.05 | ≤ 0.15 |

All Tempers of 2219 Aluminum Alloy

The 2219 aluminum alloy is available in multiple tempers, each providing distinct mechanical and physical properties suitable for various applications.

Below is an overview of the common tempers:

| Temper | Description |

|---|---|

| O (Annealed) | Fully annealed for maximum workability but with lower strength. |

| T3 | Solution heat-treated and cold worked for improved strength. |

| T37 | A specialized temper designed for optimized mechanical properties. |

| T6 | Solution heat-treated and artificially aged for maximum strength. |

| T81 | Solution heat-treated and cold worked to a higher strength level. |

| T87 | Solution heat-treated and artificially aged to enhance strength and resistance to stress corrosion cracking. |

| T851 | Solution heat-treated, stress relieved by stretching, and artificially aged to provide high strength with improved stress corrosion resistance. |

Each temper variation offers different levels of hardness, ductility, and resistance to environmental and mechanical stresses, making 2219 aluminum alloy highly versatile in various industries.

Properties and Characteristics of 2219 T37 Aluminum Sheet

2219 T37 aluminum sheet offers an excellent balance of strength, durability, and corrosion resistance. Below are its key properties:

- High Strength: The alloy maintains its strength at high temperatures, making it suitable for aerospace applications.

- Corrosion Resistance: Excellent resistance to atmospheric and chemical corrosion.

- Thermal Stability: Withstands high temperatures without significant loss of mechanical properties.

- Machinability: Easily machinable with standard tools.

- Weldability: Highly weldable, particularly with tungsten inert gas (TIG) and metal inert gas (MIG) welding methods.

- Fatigue Resistance: Excellent performance under cyclic loads.

Applications of 2219 T37 Aluminum Sheet

2219 T37 aluminum sheet is widely used across multiple industries due to its excellent strength, high thermal stability, and corrosion resistance. Below are the key application areas where this aluminum sheet is commonly utilized:

1. Aerospace Industry

2219 T37 aluminium sheet is a preferred material in the aerospace sector, primarily for manufacturing structural components in aircraft and spacecraft. Its high strength-to-weight ratio and superior heat resistance make it ideal for:

- Fuselage and wing components – Provides excellent structural integrity.

- Fuel tanks and cryogenic applications – Resistant to extreme temperatures and pressure variations.

- Engine components – Withstands high thermal and mechanical stresses.

2. Defense and Military Applications

Due to its durability and ability to perform under extreme conditions, 2219 T37 aluminum sheet is used in various defense applications, such as:

- Armored vehicle components – Provides lightweight yet durable protection.

- Missile and weapon system parts – Enhances reliability in high-stress environments.

- Military-grade aerospace structures – Used in defense aircraft and UAVs.

3. Marine Industry

Marine vessels require materials that resist corrosion from saltwater environments. 2219 T37 aluminum sheet is used for:

- Ship and submarine structural components – Ensures longevity and strength.

- Heat exchangers and piping systems – Maintains thermal efficiency.

- Decking and interior structures – Offers a lightweight and corrosion-resistant solution.

4. Automotive and Motorsports

High-performance vehicles benefit from the strength and thermal properties of 2219 aluminum sheet. It is used for:

- Engine and transmission components – Resists heat and mechanical wear.

- Lightweight structural panels – Reduces weight while maintaining durability.

- High-performance exhaust systems – Ensures longevity under extreme conditions.

5. Industrial Manufacturing

2219 T37 aluminum sheet is also employed in general industrial applications, including:

- Heat exchangers and thermal management systems – Facilitates effective heat dissipation.

- Mold manufacturing – Provides a stable and machinable material for precision components.

- Structural framework for machinery – Ensures strength and stability.

6. Scientific Research and High-Tech Applications

Due to its unique properties, this alloy is used in cutting-edge research and high-tech applications such as:

- Satellite structures – Offers stability in extreme space environments.

- Cryogenic storage tanks – Maintains structural integrity at very low temperatures.

- Advanced robotics and automation – Provides a durable and lightweight framework.

7. High-Temperature Applications

2219 T37 aluminum sheet is ideal for environments that demand high-temperature performance, such as:

- Heat shielding in industrial furnaces – Prevents structural degradation.

- Aerospace propulsion systems – Enhances thermal stability.

- Power generation equipment – Used in turbines and exhaust systems.

This diverse range of applications makes 2219 aluminum sheet valuable across multiple industries, especially in those requiring high strength, temperature resistance, and durability.

Advantages of Using 2219 T37 Aluminum Sheet

- Lightweight: High strength-to-weight ratio enhances fuel efficiency in aerospace and automotive applications.

- Superior Weldability: Ideal for joining components with welding techniques.

- Corrosion Resistance: Durable in harsh environments.

- High Thermal Stability: Suitable for high-temperature applications.

- Excellent Machinability: Allows for precision machining with minimal tool wear.

Comparison with Other Aluminum Sheet Alloys

| Property | 2219 T37 | 6061 T6 | 7075 T6 |

|---|---|---|---|

| Strength | High | Medium | Very High |

| Corrosion Resistance | Excellent | Good | Moderate |

| Weldability | Excellent | Good | Poor |

| Thermal Stability | High | Moderate | Low |

| Machinability | Good | Excellent | Moderate |

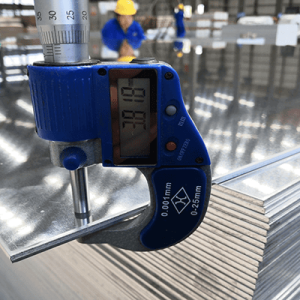

Manufacturing Processes of 2219 T37 Aluminum Sheet

The production of 2219 T37 aluminum involves several key steps:

- Casting: Raw aluminum and copper are melted and cast into billets.

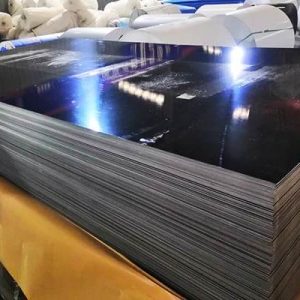

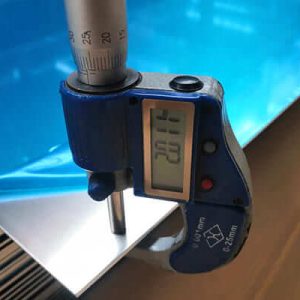

- Rolling: The billets are rolled into sheets of various thicknesses.

- Solution Heat Treatment: Enhances mechanical properties.

- Cold Working: Improves strength and durability.

- Aging: Stabilizes the alloy to achieve the T37 temper.

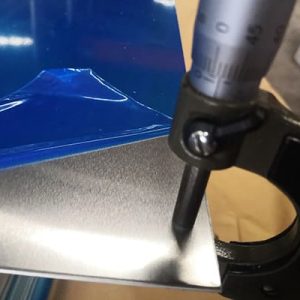

- Quality Control: Each batch undergoes rigorous testing for strength, corrosion resistance, and dimensional accuracy.

Where to Buy 2219 T37 Aluminum Sheet

When looking for high-quality 2219 T37 aluminum sheet, choosing a reliable supplier is essential to ensure superior performance, consistency, and compliance with industry standards. One such trusted supplier is Langhe Aluminum.

Key advantages of purchasing from Langhe Aluminum:

- High-Quality Standards – All materials meet international specifications, including ASTM, AMS, and aerospace industry requirements.

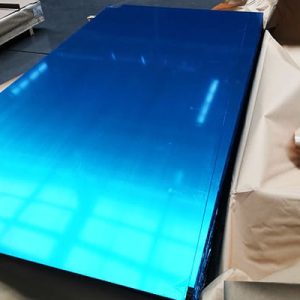

- Custom Processing Options – Provides custom-cut sizes, thickness variations, and surface treatments to meet specific project needs.

- Global Supply Chain – Efficient logistics and worldwide shipping ensure timely delivery to customers across different regions.

- Technical Support – Expert consultation for selecting the right material based on performance requirements and application needs.

For industries requiring high-strength, heat-resistant aluminum sheets, Langhe Aluminum stands out as a trustworthy supplier with a commitment to excellence.

Cost Considerations and Pricing Factors

Several factors influence the cost of 2219 T37 aluminium sheet:

- Raw Material Costs: Fluctuations in aluminum and copper prices.

- Processing Complexity: Heat treatments and rolling processes add to production costs.

- Supply and Demand: Aerospace and defense industry demand affects pricing.

- Sheet Thickness and Size: Larger and thicker sheets are more expensive.

- Additional Processing: Custom cutting, surface treatments, and coatings increase costs.

Conclusion

2219 T37 aluminum sheet is a premium material with exceptional strength, corrosion resistance, and thermal stability, making it ideal for aerospace, defense, marine, and industrial applications. Its superior weldability and machinability further enhance its usability. When selecting 2219 T37 aluminium sheet, it is essential to consider factors such as application requirements, cost, and availability from reputable suppliers.

Langhe Website: https://langhe-metal.com/ & https://langhe-industry.com/

Related Products

Related products

-

Aluminum Sheet Plate

6063 Aluminum Sheet: Achieve Flawless Finishes

0 out of 5¥5,800.00Known for its exceptional surface quality and superior anodizing response, 6063 Aluminum Sheet is the ideal material for architectural trim, decorative components, and applications where aesthetics are paramount.

-

Aluminum Sheet Plate

Amazing 2024 Aluminum Sheet – The Ultimate Strength Breakthrough

0 out of 5¥6,500.00Explore premium 2024 aluminum sheet, offering exceptional fatigue resistance and elevated tensile strength for aerospace, defense, and high‑performance engineering. Available in T3, T4, and T6 tempers.

-

Aluminum Sheet Plate

5086 Aluminum Sheet

0 out of 5¥3,750.00Unlock the technical advantages of 5086 Aluminum Sheet. In-depth analysis of its durability, excellent weldability, and supreme corrosion proofing for critical structures and harsh conditions.

-

Aluminum Sheet Plate

Honeycomb aluminum panel

0 out of 5¥4,500.00Discover how honeycomb aluminum panel deliver superior flexural stiffness, thermal insulation, and fire safety—all at 70% less weight than solid metal. Ideal for façades, aerospace, and industrial design.

-

Aluminum Sheet Plate

3105 Aluminum Sheet

0 out of 5¥3,450.00Learn why 3105 aluminum sheet is the go-to for packaging, construction, and transportation. With tensile strength up to 210 MPa (H34 temper), food-grade safety, and easy deep drawing, it delivers…

-

Aluminum Sheet Plate

5052 Aluminum Sheet

0 out of 5¥5,880.005052 aluminum sheet belongs to the 5000 series aluminum alloy. The main added element is Mg. It is obtained by rolling the aluminum alloy. It has strong corrosion resistance and…

-

Aluminum Sheet Plate

3003 Aluminum Plate

0 out of 5¥3,350.003003 aluminum plate: corrosion-resistant, formable, ideal for tanks, roofing & transport. Available in H14/H24/O tempers, thickness 0.2-150mm. Choose mill, embossed or painted finishes.

-

Aluminum Sheet Plate

1000 Series Aluminum Sheet

0 out of 5¥3,250.001000 series aluminum sheet: known for its excellent corrosion resistance, high electrical conductivity, and formability. Ideal for applications in chemical equipment, food processing, and architectural projects

-

Aluminum Sheet Plate

5754 Aluminum Sheet

0 out of 5¥5,208.005754 aluminum plate is widely used due to its excellent strength-to-weight ratio, corrosion resistance and machinability. Such as: aerospace, automobile, ship, construction applications, pressure vessel landing, etc.

-

Aluminum Sheet Plate

1060 Aluminum Sheet

0 out of 5¥3,468.001060 aluminum plate is a common lightweight material belonging to the 1000 series aluminum alloy. It is popular in the market due to its low price, strong corrosion resistance and…