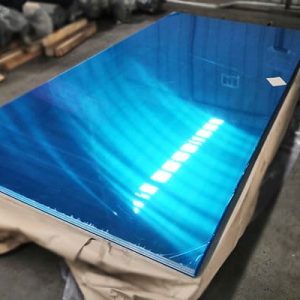

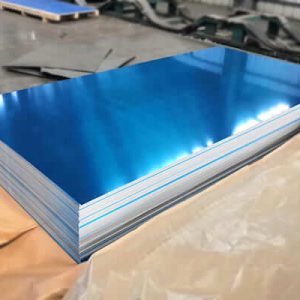

5052 Hoja de aluminio

5052 la hoja de aluminio pertenece al 5000 aleación de aluminio en serie. El principal elemento agregado es mg. Se obtiene rodando la aleación de aluminio. It has strong corrosion resistance and excellent machinability and is widely used.

1. 5052 Aluminum Sheet Overview

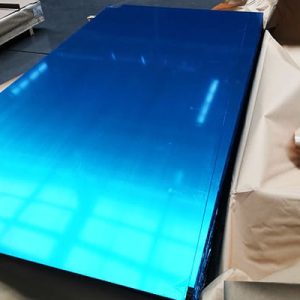

5052 aluminum sheet represents one of the most widely used aluminum alloys in sheet form.

This material enjoys a strong reputation among engineers and fabricators alike due to its superb balance of strength, Formabilidad, y excelente resistencia a la corrosión.

1.1 Definición de 5052 Hoja de aluminio

5052 aluminum sheet defines a non-heat-treatable alloy within the 5000 series that uses magnesium as the primary alloying element along with a trace addition of chromium.

Manufacturers produce 5052 aluminum sheet by starting with high-purity aluminum and blending in the alloying elements to achieve an optimal balance.

The alloy typically contains approximately 97.2%–98.9% aluminum, with magnesium levels ranging between 2.2% y 2.8% and chromium levels from 0.15% a 0.35%.

These percentages produce a material with improved mechanical strength, enhanced fatigue resistance, and an outstanding resistance to corrosive environments.

1.2 Overview of Its Importance in Various Industries

5052 aluminum sheet serves a critical role in many industries.

Its excellent resistance to corrosion, especially in marine atmospheres, along with its exceptional formability, make it indispensable in both traditional and advanced applications.

Many industries benefit from 5052 aluminum sheet in the following ways:

- Aplicaciones marinas: The alloy withstands saltwater corrosion, making it a top choice for shipbuilding, estructuras marinas, and offshore equipment.

- Aerospace and Transportation: Lightweight design paired with high fatigue resistance and good weldability supports its use in aerospace components, aircraft skins, and vehicle chassis.

- Industria automotriz: Engineers favor 5052 for body panels, corchetes, and other structural components due to its strength-to-weight ratio.

- Edificio y construcción: In architectural applications, the material exhibits durability and aesthetic appeal when used in cladding, techumbre, y paneles decorativos.

- Industrial and Electronic Sectors: Its excellent mechanical properties suit the production of pressure vessels, recintos electrónicos, and heat exchangers.

- General Sheet Metal Fabrication: Its ease of cold working enables manufacturers to produce precision parts such as containers, conducto, and customized fabricated assemblies.

The alloy’s versatility has led to robust global demand, where its performance characteristics deliver both economic and technical benefits.

Industries choose 5052 aluminum sheet when they require a material that meets strict durability, safety, and sustainability standards.

2. Material Properties and Performance Parameters

A deep understanding of the material properties and performance parameters of 5052 aluminum sheet enables its optimal application.

This section explains the alloy classification, composición, and the key mechanical, physical, and environmental properties that define this material.

2.1 Alloy Classification and Composition

5052 belongs to the 5xxx series aluminum alloys that primarily use magnesium as the key alloying element.

Its composition design helps achieve a well-balanced combination of strength, ductilidad, y resistencia a la corrosión.

2.1.1 Componentes principales

The primary component of 5052 aluminum sheet is high-purity aluminum, which forms the matrix.

Típicamente, the aluminum content accounts for approximately 97.2% a 98.9% of the alloy.

This high aluminum base provides excellent conductivity, low density, and inherent malleability.

2.1.2 Elementos auxiliares

Magnesium plays a crucial role in enhancing the material’s strength through solid solution strengthening.

En 5052 hoja de aluminio, the magnesium content usually ranges between 2.2% y 2.8%.

The small addition of chromium—approximately 0.15% to 0.35%—further contributes to improved corrosion resistance and stabilization of the microstructure.

2.1.3 Elementos e impurezas traza

To maintain consistency and high performance, manufacturers strictly control the levels of impurities and trace elements.

The common controlled elements include:

- Hierro (Ceñudo): Kept below 0.40%

- Silicio (Y): Maintained at or below 0.25%

- Cobre (Cu): Limited to a maximum of 0.10%

- Manganeso (Minnesota): Typically below 0.10%

- Zinc (Zn): Kept below 0.10%

Controlling these impurities prevents adverse effects such as reduced ductility, diminished corrosion resistance, or inconsistent mechanical behavior.

Tabla de composición química

| Elemento | Typical Content (%) | Role/Impact |

|---|---|---|

| Aluminio | 97.2 | Base metal providing low density, alta conductividad |

| Magnesio | 2.2 - 2.8 | Strengthens through solid solution strengthening |

| Cromo | 0.15 - 0.35 | Enhances corrosion resistance and micro |

| Hierro | ≤ 0.40 | Minimal amounts ensure no negative impact on ductility |

| Silicio | ≤ 0.25 | Maintains workability, minimizes brittleness |

| Cobre | ≤ 0.10 | Kept low |

| Manganeso | ≤ 0.10 | Helps stabilize the alloy structure |

| Zinc | ≤ 0.10 | Limited to prevent undesirable reactions |

2.2 Propiedades mecánicas

Mechanical performance is the cornerstone of selecting 5052 aluminum sheet in engineering applications.

Key mechanical properties include tensile strength, fuerza de rendimiento, alargamiento, and modulus of elasticity.

- Resistencia a la tracción: 5052 aluminum sheet typically exhibits an ultimate tensile strength around 228 MPA (aproximadamente 33,000 psi) in hardened conditions such as H32 temper.

- Fuerza de rendimiento: The yield strength usually measures approximately 193 MPA (acerca de 28,000 psi) in the H32 temper.

- Alargamiento: The material demonstrates moderate ductility, with elongation values ranging from 8% a 20% depending on the temper.

- Módulo de elasticidad: The modulus measures around 70 GPA, indicating good stiffness relative to its lightweight nature.

- Resistencia al corte: 5052 aluminum offers sufficient resistance to shear forces, an important factor during bending and forming operations.

Mechanical Properties Table (Example Data for H32 Temper)

| Propiedad | Valor (Métrico) | Valor (Imperial) |

|---|---|---|

| Resistencia a la tracción definitiva | ~228 MPa | ~33,000 psi |

| Fuerza de rendimiento | ~193 MPa | ~ 28,000 psi |

| Alargamiento | 8 - 12 | - |

| Módulo de elasticidad | ~70 GPa | ~10,200 ksi |

| Resistencia al corte | ~138 MPa | ~ 20,000 psi |

The process of cold working, which increases strength by inducing work hardening, significantly affects these mechanical parameters.

The alloy cannot be heat-treated to further increase strength, so the tempering process during cold working becomes paramount.

2.3 Propiedades físicas

5052 aluminum sheet also boasts several favorable physical properties, making it versatile in a range of applications:

- Densidad: The density stands at approximately 2.68 g/cm³, which provides an excellent strength-to-weight ratio.

- Punto de fusión: The melting range lies between 607°C and 650°C, typical for aluminum alloys.

- Conductividad térmica: With a thermal conductivity of around 138 W/m · k, the material efficiently disperses heat, making it suitable for applications requiring heat exchange.

- Coeficiente de expansión térmica: The alloy exhibits a moderate coefficient of thermal expansion, alrededor 23.7 x 10^–6/°C.

- Conductividad eléctrica: The alloy retains good electrical conductivity, which remains important in many electronic and structural applications.

2.4 Environmental Resistance

5052 aluminum sheet stands out for its exceptional resistance to various environmental conditions:

- Resistencia a la corrosión: The natural formation of a protective aluminum oxide layer guards the underlying metal. Its chemistry, particularly the low copper content, further enhances its resistance to saltwater and acidic conditions.

- Fatiga: The alloy also exhibits high fatigue strength, which is vital in applications subject to repetitive loading.

- Soldabilidad y formabilidad: While excellent in corrosive environments, the alloy also maintains good weldability and formability in both static and dynamic use.

- Resistance to Extreme Conditions: In addition to high moisture and salt resistance, the alloy shows stability in both low and high temperature environments, ensuring durability over a long lifespan.

3. Proceso de producción de 5052 Hoja de aluminio

The production process for 5052 aluminum sheet employs several advanced, controlled methods to ensure the final product meets rigorous quality standards.

Manufacturers emphasize precision and efficiency through every step from raw material selection to final packaging.

3.1 Preparación de materia prima

Manufacturers begin by selecting high-purity aluminum along with the necessary alloying elements (magnesium and chromium) based on strict quality criteria.

They source the best available materials and carry out initial testing to verify chemical compositions.

Quality assurance professionals run spectrometric tests and chemical analysis to ensure that impurities remain below the set thresholds.

3.2 Melting and Casting Process

The next stage involves melting the pre-blended raw material in high-capacity furnaces, ensuring complete homogenization:

- Fusión: Operators heat the materials to a temperature where all alloying elements dissolve uniformly into molten aluminum. This step ensures the chemical composition remains consistent.

- Fundición: The molten alloy flows into continuous casting molds or ingot molds. Continuous casting helps reduce gas entrapment and ensures a uniform grain structure in the resulting billets.

3.3 Rolling caliente y rodante áspero

After casting, billets enter the hot rolling phase where the primary reduction in thickness occurs:

- Preheating: Billets reheat to optimal rolling temperatures (often above 400°C) to enhance ductility.

- Rodadura áspera: Billets pass through a series of heavy-duty rollers that reduce thickness significantly while aligning the grain structure.

- Intermediate Measurements: Operators check dimensions and quality continuously to ensure uniform reduction.

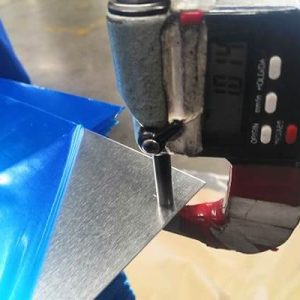

3.4 Proceso de laminación de frío

Después de Rolling Hot, manufacturers shift to cold rolling to achieve the final gauge:

- Sequential Passes: The sheet passes through multiple cold rollers that incrementally reduce thickness further.

- Precision Control: Close monitoring of thickness and surface finish; adjustments occur in real time to ensure optimal consistency.

- Trabajar endureciendo: Cold rolling simultaneously increases strength through work-hardening while preserving ductility.

3.5 Tratamiento de recocido

Cold-rolled sheets accumulate internal stresses that require relief through annealing:

- Tratamiento térmico: Operators heat the cold-rolled sheet to a predetermined temperature (typically around 343°C to 650°F) to allow recovery of ductility.

- Holding Time: Maintain the temperature for a specific period to ensure uniform stress relief.

- Controlled Cooling: Cooling occurs either in air or under controlled conditions to maintain the improved properties.

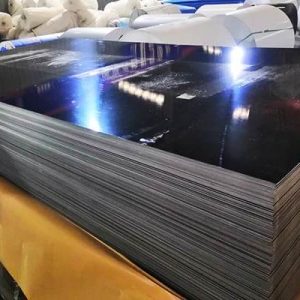

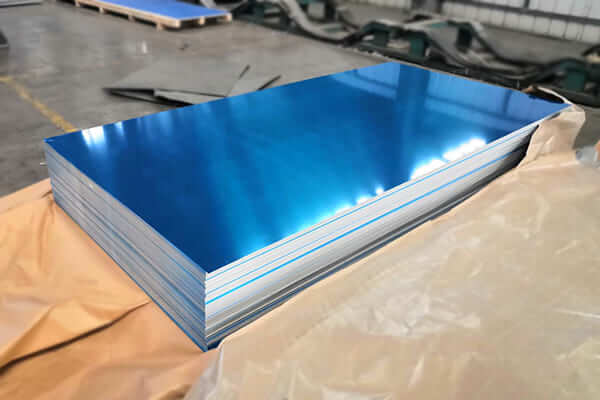

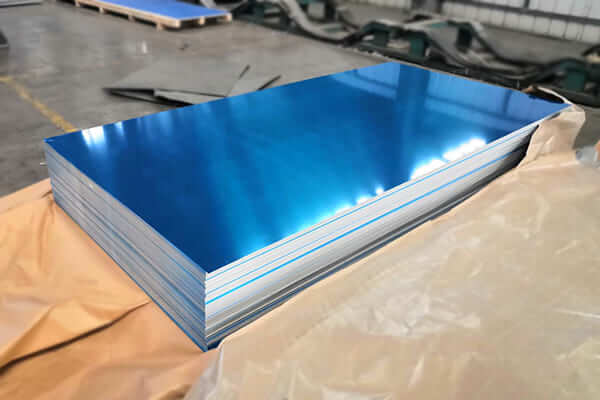

3.6 Edge Cutting, Guarnición, and Coil Packaging

The annealed sheet then undergoes final finishing processes:

- Edge Cutting and Trimming: Machines trim the edges to remove irregularities and achieve precise widths.

- Coil Formation: The sheet winds onto cores to form rolls, which facilitates handling, shipping, and subsequent fabrication.

- Embalaje: Manufacturers package the rolls securely, marking them with essential batch and specification information.

3.7 Key Control Points and Quality Monitoring

Quality monitoring remains a continuous process throughout production:

- In-Line Measurements: Automated systems check thickness, ancho, and surface finish continuously.

- Inspecciones de superficie: Visual and optical inspection systems detect defects such as scratches, blisters, or contamination.

- Análisis químico: Regular spectrometric testing verifies that the chemical composition remains within strict limits.

- Prueba mecánica: De tensión, producir, and elongation tests confirm that mechanical properties meet the required standards.

- Process Documentation: Operators document all process parameters to ensure full traceability and to support continuous improvement initiatives.

4. Especificaciones comunes y tipos de productos

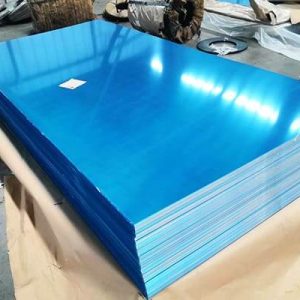

5052 aluminum sheet products vary widely in terms of thickness, ancho, templado, and form factors.

Understanding the common specifications helps fabricators and engineers select the right product for their application.

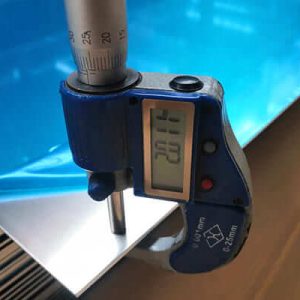

4.1 GRESSE Y ANCHO RANGO

Manufacturers produce 5052 aluminum sheet in a range of thicknesses and widths to cater to diverse industrial needs:

- Rango de grosor: Typically ranges from as thin as 0.2 mm hasta 6.0 mm or more. Applications in aerospace and electronics may require very thin gauge, while structural applications require thicker sheets.

- Rango de ancho: Sheets come in standard widths ranging from 500 mm to over 1600 mm. Custom widths may also be produced based on customer specifications.

Example Specification Table

| Especificación | Range/Standard Values |

|---|---|

| Espesor | 0 |

| Ancho | 500 MM - |

| Longitud (per roll) | 1000 m – 3000 metro |

4.2 Estados de temperamento diferentes

Tempering of 5052 aluminum sheet affects its mechanical properties significantly. The two main temper conditions are:

- O temperamento (Annealed State): The sheet remains fully annealed. It features excellent formability and is very soft, which benefits applications where intricate forming is necessary.

- H Temper (Endurecido por la tensión): The sheet undergoes cold working to increase its strength. Common sub-classifications include H32, H34, H36, and H38. Each level indicates a different hardness and strength profile.

- H32: Offers a balance of good strength and moderate formability.

- H34: Provides higher strength and hardness than H32, suitable for applications demanding enhanced structural performance.

- H36 and H38: Typically used for higher-performance applications where maximizing strength is critical.

4.3 Customized Products and Standard Products

Manufacturers offer both standard and customized products:

- Productos estándar: Follow widely accepted industry dimensions and tempering conditions. They meet regular commercial needs.

- Productos personalizados: Fabricators can tailor dimensions, templado, edge finishes, and packaging to meet unique customer specifications. Customized orders often require close collaboration between the customer and the manufacturer to achieve optimal results.

5. Application of 5052 Hoja de aluminio

5052 aluminum sheet finds widespread usage across numerous industries.

Its unique combination of strength, resistencia a la corrosión, and ease of fabrication makes it a versatile material.

5.1 Marine and Aerospace Applications

5052 aluminum sheet proves ideal in harsh environmental conditions:

- Ambientes marinos: Its superb resistance to saltwater corrosion makes it essential for shipbuilding, offshore platforms, and marine equipment.

- Aplicaciones aeroespaciales: The alloy’s high strength-to-weight ratio supports its use in aircraft structures, paneles de fuselaje, and aerospace components. Its fatigue resistance under cyclic loading makes it a preferred choice in aviation design.

5.2 Automotriz y transporte

5052 aluminum sheet also serves the automotive industry:

- Paneles de cuerpo: The material’s formability and strength enable the manufacture of complex shapes required for car body panels and structural reinforcements.

- Brackets and Enclosures: Used in constructing brackets, escudos de calor, and other components due to its durability and lightweight nature.

- Equipo de transporte: It finds use in vehicle frames, truck bodies, and rail equipment, where reliability and cost-efficiency are paramount.

5.3 Building and Construction Uses

The construction sector benefits from the aesthetic and structural properties of 5052 hoja de aluminio:

- Revestimiento arquitectónico: The material’s decorative finish and durability make it a popular choice for cladding and facade panels.

- Techado y revestimiento: Its lightweight nature and resistance to weathering suit it for roofing applications.

- HVAC Components: Use in ductwork and heat exchangers improves energy efficiency in buildings.

5.4 Aplicaciones industriales y electrónicas

Industries and electronics also rely on 5052 hoja de aluminio:

- Recintos electrónicos: The material’s good conductivity and corrosion resistance protect sensitive electronic components.

- Intercambiadores de calor: Its high thermal conductivity allows efficient heat dissipation.

- Pressure Vessels and Tanks: Used in chemical processing and hydraulic systems thanks to robust mechanical properties and environmental resistance.

- Machined Components: Serves as a substrate for precision machined parts in a variety of industrial contexts.

5.5 General Sheet Metal Processing and Fabrication

5052 aluminum sheet proves versatile in general sheet metal operations:

- Forming and Bending: The alloy excels in cold-working processes. It bends without cracking, making it ideal for complex fabrications.

- Stamping and Drawing: Manufacturers use it to stamp or draw parts with intricate designs.

- Fabricación personalizada: Industries favor 5052 aluminum for its ease of customization in components ranging from containers to custom brackets.

5.6 Aplicaciones especiales

Certain niche applications leverage the unique properties of 5052 hoja de aluminio:

- Renewable Energy: The material appears in solar panel frames and energy-efficient architectural projects.

- Medical Devices: Its non-toxic, corrosion-resistant nature makes it suitable for medical equipment housings and instrument panels.

- Signage and Displays: Its smooth finish and high aesthetic value support the production of high-quality signs and nameplates.

- Industrial Automation: The alloy finds use in robotic enclosures and machine guarding due to its durability and ease of fabrication.

6. Estándares, Pruebas, y certificación

Asegurando la calidad de 5052 aluminum sheet relies on adherence to multiple standards and rigorous testing protocols.

Manufacturers and end users reference internationally recognized specifications to guarantee performance.

6.1 Estándares y especificaciones relevantes de la industria

5052 aluminum sheet complies with several standards set by organizations such as ASTM, ISO, BS, y.

Some commonly referenced standards include:

- ASTM B209: Especifica los requisitos para la lámina y placa de aluminio y aleación de aluminio..

- EN 485-2: European standard for aluminum sheet products.

- ISO 9001: Quality management systems that many manufacturers follow to ensure consistent quality.

- BS EN 573-3: Pertains to the chemical composition of aluminum alloys.

Manufacturers document compliance with these standards to demonstrate product reliability, ensuring that all material properties remain within permissible limits as established by these governing bodies.

6.2 Test Methods and Quality Certification

Effective quality control of 5052 aluminum sheet employs a variety of test methods:

- Análisis químico: Use of spectroscopy and other analytical methods confirms that chemical compositions meet established specifications.

- Prueba mecánica: Resistencia a la tracción, fuerza de rendimiento, alargamiento, and other mechanical properties receive validation through standardized tests (P.EJ., according to ASTM B209).

- Mediciones dimensionales: Laser gauges and ultrasonic thickness testers ensure precise thickness and width.

- Inspección de la superficie: Visual and automated optical inspections check for surface defects, ensuring that the sheet meets high-quality standards.

- Prueba de corrosión: Accelerated salt spray and immersion tests predict long-term environmental resistance.

- Proceso de dar un título: Manufacturers secure quality certifications such as ISO 9001 and others from independent laboratories to validate performance. They also provide traceability documentation and batch test reports for customer assurance.

Example Quality Certification Checklist:

- Chemical Composition Report

- Tensile and Yield Test Data

- Dimensional Tolerance Records

- Surface Quality Inspection Reports

- Corrosion Resistance Test Results

- ISO 9001 Certification Documentation

7. Preguntas frecuentes (Preguntas frecuentes)

This section answers common queries and provides clarifications regarding 5052 hoja de aluminio.

7.1 How is 5052 Aluminum Sheet Different from Other Aluminum Sheets?

5052 aluminum sheet differs primarily in its alloy composition.

It uses magnesium as the principal alloying element and includes trace amounts of chromium.

This composition delivers an excellent balance of strength, resistencia a la corrosión, y formabilidad, setting it apart from purer grades (como 1100) or heat-treatable alloys (como 6061).

Its ability to undergo cold work without further heat treatment marks its unique position in the 5000 serie.

7.2 How is the Hygienic Safety of 5052 Aluminum Sheet Guaranteed?

Manufacturers guarantee the hygienic safety of 5052 aluminum sheet by:

- Strict Raw Material Selection: Sourcing high-purity aluminum and controlling impurity levels.

- Clean Production Environment: Maintaining contamination-free production areas.

- Tratamiento superficial: Ensuring the sheet remains free from contaminants through surface cleaning and protective oxide layer formation.

- Testing and Certification: Conducting frequent tests and securing certifications (P.EJ., FDA approval for certain applications) to assure product safety in applications such as food packaging and medical devices.

7.3 Which Tempering Conditions of 5052 Aluminum Sheet Are Suitable for Specific Applications?

The temper of 5052 aluminum sheet influences its mechanical properties:

- O temperamento (Recocido): Ideal for applications requiring maximum formability, where complex shapes and bending are necessary.

- H32 temperamento: Offers a balanced mix of strength and ductility, perfect for fabricated parts that require moderate strength without excessive stiffness.

- H34/H36/H38 Temper: Provide higher strength and are used when increased load-bearing capacity is needed but might come with reduced formability. Select the temper based on your application’s specific mechanical stress and forming requirements.

7.4 How Do Manufacturers Control Thickness Tolerances and Surface Quality During Production?

Manufacturers implement robust quality control measures:

- Real-Time Monitoring: Automated in-line systems measure thickness and width continuously.

- Precision Equipment: Use of laser or ultrasonic gauges ensures precise and uniform dimensions.

- Regular Inspections: Visual and optical inspections detect surface defects early.

- Process Adjustments: Operators adjust rolling pressure, speed, and annealing conditions immediately if deviations occur.

- Quality Documentation: Each batch gets detailed records to validate compliance with tolerance specifications.

7.5 How to Evaluate the Environmental Impact and Recyclability of 5052 Hoja de aluminio?

Evaluating the environmental benefits includes:

- Reciclabalidad: Aluminum recycles efficiently with minimal degradation in properties. Recycling aluminum requires substantially less energy than primary production.

- Life Cycle Analysis (LCA): LCA studies detail the total energy consumption, greenhouse gas emissions, and material usage from production to disposal.

- Certifications and Environmental Audits: Independent environmental audits and certifications (P.EJ., ISO 14001) validate sustainable practices.

- Beneficios de la economía circular: Evaluate how the material integrates into sustainable cycles, reducing waste and supporting eco-friendly practices.

- Energy Savings Metrics: Compare energy consumption between primary production and recycling to underscore the environmental advantages.

8. Resumen

In this comprehensive article, we examined 5052 aluminum sheet from multiple perspectives.

We started by defining the material and highlighting its significance in industries ranging from marine and aerospace to automotive, construcción, y aplicaciones industriales.

Artical delved into the alloy’s composition, discussing its main components (high-purity aluminum), auxiliary elements (magnesium and chromium), and trace impurities that manufacturers rigorously control.

We outlined the key mechanical and physical properties—including tensile strength, fuerza de rendimiento, alargamiento, density, conductividad térmica, and corrosion resistance—that make 5052 aluminum sheet an attractive choice for engineers and designers.

The article then provided a detailed overview of the manufacturing process.

We covered raw material preparation, melting and casting, Rolling caliente y fría, recocido, edge trimming, and coil packaging.

Emphasis was placed on the key control points and quality monitoring protocols that ensure dimensional and chemical consistency.

Además, we reviewed common specifications including thickness and width ranges, tempering states (O, H32, H34, etc.), and the availability of both standardized and custom products.

The discussion on applications demonstrated how the unique properties of 5052 aluminum sheet serve marine, aeroespacial, automotor, building, industrial, and even special niche applications where reliability and sustainability matter.

More products about Langhe: https://langhe-alu.com/products/

Productos relacionados

Productos relacionados

-

Placa de aluminio

De alta resistencia 2024 Placa de hoja de aluminio: rendimiento liviano superior

0 fuera de 5¥6,800.00Eleve sus proyectos con 2024 Placa de aluminio, ofreciendo una relación de fuerza -peso excepcional, Excelente resistencia a la corrosión, y resistencia a la fatiga confiable: ideal para aeroespacial, automotor, y aplicaciones marinas.

-

Placa de aluminio

6063 Hoja de aluminio: Lograr acabados impecables

0 fuera de 5¥5,800.00Conocido por su excepcional calidad de superficie y respuesta de anodización superior, 6063 La hoja de aluminio es el material ideal para los adornos arquitectónicos, componentes decorativos, y aplicaciones donde la estética es primordial.

-

Placa de aluminio

5454 Placa de aluminio

0 fuera de 5¥3,600.00Elegir 5454 Placa de aluminio para resistencia ligera en mazos marinos, buques químicos, y contenedores de presión. Confiabilidad comprobada, Fabricación fácil.

-

Placa de aluminio

5083 Hoja de aluminio

0 fuera de 5¥3,780.00Descubrir de alto rendimiento 5083 hoja de aluminio, diseñado para construcción naval, automotor, y aplicaciones estructurales. Resistencia a la corrosión superior, soldadura, y durabilidad.

-

Placa de aluminio

Panel de aluminio de panal

0 fuera de 5¥4,500.00Descubre cómo el panel de aluminio de Honeycomb ofrece rigidez de flexión superior, aislamiento térmico, y seguridad contra incendios, todo en 70% menos peso que el metal sólido. Ideal para hacerte, aeroespacial, y diseño industrial.

-

Placa de aluminio

1070 Placa de aluminio

0 fuera de 5¥3,300.00Explore la composición química, resistencia a la corrosión, y proceso de fabricación de 1070 hoja de aluminio. Vea por qué los ingenieros lo eligen para barras de autobús, intercambiadores de calor, y paneles decorativos.

-

Placa de aluminio

3104 Hoja de aluminio

0 fuera de 5¥3,500.00Explore las características clave de 3104 hoja de aluminio, incluyendo su excelente resistencia a la corrosión, Formabilidad, y fuerza. Comprender su proceso de producción y cómo se compara con otras aleaciones de aluminio en el…

-

Placa de aluminio

1100 Hoja de aluminio

0 fuera de 5¥3,482.001100 Hoja de aluminio Excelente resistencia a la corrosión, Formabilidad, y la conductividad lo hace ideal para aplicaciones en equipos químicos, procesamiento de alimentos, y proyectos arquitectónicos. Aprenda por qué es una opción superior para industrial…

-

Placa de aluminio

5754 Hoja de aluminio

0 fuera de 5¥5,208.005754 La placa de aluminio se usa ampliamente debido a su excelente relación resistencia a peso, Resistencia a la corrosión y maquinabilidad. Como: aeroespacial, automóvil, barco, aplicaciones de construcción, aterrizaje por embarcación a presión, etc..

-

Placa de aluminio

1060 Hoja de aluminio

0 fuera de 5¥3,468.001060 La placa de aluminio es un material ligero común que pertenece al 1000 aleación de aluminio en serie. Es popular en el mercado debido a su bajo precio, fuerte resistencia a la corrosión y…